We extensively use stainless steel wire in industrial filtration thanks to its corrosion resistance, strength, and ability to maintain integrity under various conditions. Here are some applications across different industries:

1. Petrochemical Industry: We use stainless steel wire in the refining process to filter out impurities—such as sulfur, nitrogen, and metals—from crude oil. It’s also crucial in the production of chemicals like ethylene, propylene, and benzene, where it withstands high temperatures and pressures.

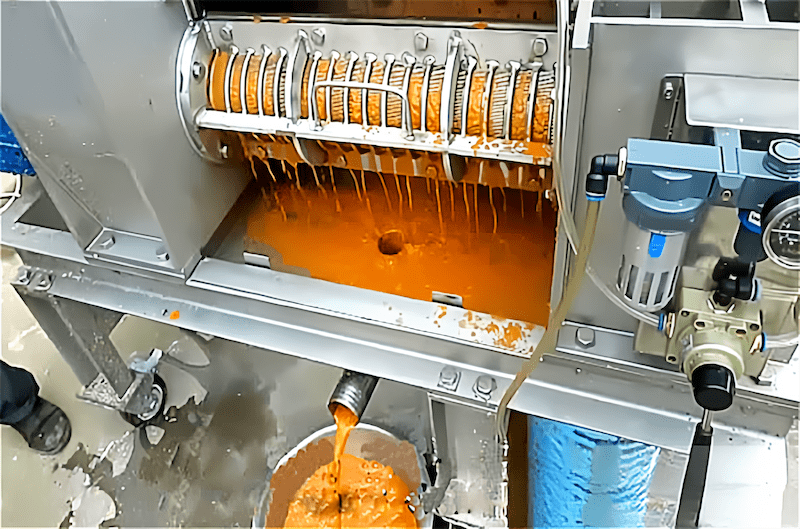

2. Food and Beverage Industry: We use it for filtering liquids such as beer, wine, and fruit juices—ensuring we remove impurities like yeast, bacteria, and sediment. This is critical for product quality and safety.

3. Juice Filtration: Stainless steel sieve tubes are vital for juice filtration, ensuring clarity and quality. Their durable, corrosion-resistant design withstands high pressure while effectively removing pulp and impurities. Easy to clean, these tubes enhance hygiene and longevity, making them essential for any juice manufacturer seeking ultimate filtration efficiency.

4. Water Treatment Industry: This industry relies on stainless steel filters for treating drinking water, wastewater, and seawater. The filters are designed to remove sediment, bacteria, and viruses, and are also used in the production of ultrapure water required by the semiconductor and electronics industries.

These applications highlight the versatility and importance of stainless steel wire in maintaining purity and safety standards in filtration processes across various sectors.