Overview of Filtration Challenges

Modern filtration systems face increasing demands for precision, durability, and efficiency. Whether in water treatment, petrochemical processing, or food production, filters must handle high pressures, corrosive environments, and varying particle sizes. Standard components often fall short in meeting these specialized needs—this is where stainless profile wire becomes essential.

5 Reasons to Choose Stainless Profile Wire

Enhanced Filtration Efficiency

Filtration performance hinges on precise control over slot size. Stainless steel wedge wire, also known as profile wire or V-wire, is a type of wire formed in a V-shape or triangular cross-section. This design allows for consistent slot openings that enable accurate separation of solids from liquids or gases. Our wedge wires are manufactured with tight tolerances through fine drawing and advanced shaping techniques.

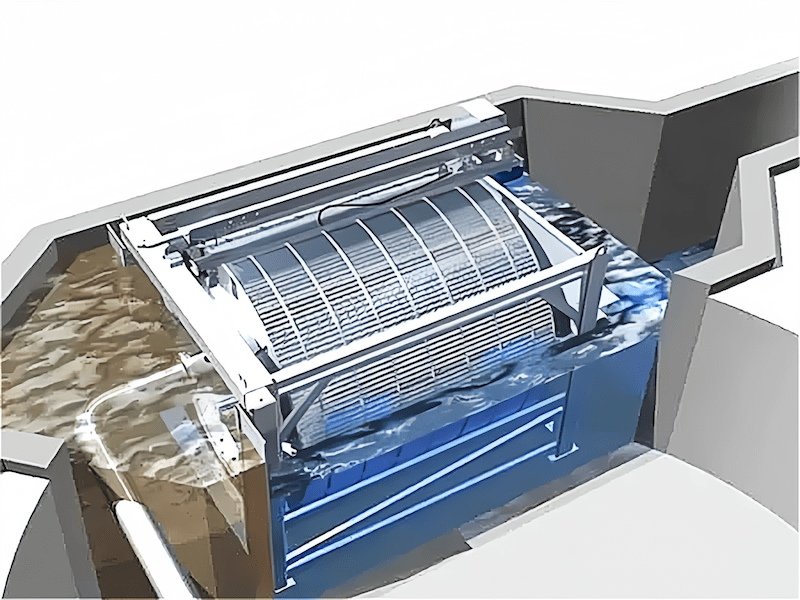

Wedge-shaped openings are created among the V-shaped wires, where fluid is passed with high efficiency and solids filtered with high effectiveness. The self-cleaning feature prevents clogging by avoiding the contact surface area of debris. This allows it to run continuously without constant maintenance shutdowns.

Higher Durability and Corrosion Resistance

We predominantly use high-quality 304 and 316L stainless steel for our profile wires. 304 and 316L stainless steel continue to be common materials due to their corrosion resistance and affordability. The materials offer excellent mechanical strength with resistance against rust in severe chemical conditions.

Wedge wire screen (water well screen) has corrosion resistance, safety and reliability, superior heat resistance, superior mechanical properties, and a long lifetime. In the process of saltwater filtration or acidic chemical treatment, our profile wires are engineered to maintain integrity under severe conditions.

Tailored Design for Specific Applications

Different industries require different filtration parameters. They are widely used in industries such as water treatment, oil and gas, mining, food processing, and pulp and paper. For example:

- In oil extraction, down hole sand control screens require robust wedge wire with tight slot tolerances.

- In water treatment, intake screens need corrosion-resistant materials with high open areas.

- In chemical processing, filters must withstand both temperature fluctuations and aggressive solvents.

Jingzhou provides customized solutions for each scenario.

Specializing in the production of various stainless steel special-shaped wires: V-shaped wire, triangular wire, wedge-shaped wire. We customize not just dimensions but also shapes—flat, trapezoidal—to match your system’s unique requirements.

Easy Maintenance and Longer Lifespan

Our V-shaped profile wires offer a key advantage: self-cleaning capability. Self-cleaning capability due to the wedge-shaped profile means fewer maintenance

Compatibility with Various Filter Systems

Our custom stainless profile wires can be integrated into multiple filter geometries, including cylindrical screens for water wells or flat panels for food processing lines.

Why Choose Jingzhou?

Reliable Quality and Technical Expertise

With three advanced production facilities covering approximately 18,000 square meters, Jingzhou’s production capacity meets the precise requirements of various applications. Every coil undergoes rigorous quality checks using infrared detectors for dimensional consistency, spectrometer analysis to verify alloy composition, tensile force meters for strength validation,and projectors to confirm tolerance levels.

Supporting Your Filtration Needs End-to-End

From sample development to bulk production, we provide full technical support, including installation guidance. Our flexible ordering process ensures you get exactly what you need—delivered promptly via sea freight or express courier worldwide.

FAQ

Q: Is customization provided?

A: Yes. Jingzhou provides various customization options like different wire diameters, opening sizes, and general dimensions. This maximizes the performance according to your application needs.

Q: How does a wedge wire prevent clogging?

A: The V-shape naturally deflects particles away from the screen surface. Self-cleaning due to the wedge-shaped profile reduces buildup that typically clogs conventional flat mesh filters.

Q: What material choices are available?

A: We work mostly with 304/316L stainless steel due to its strength. However, high-grade alloys like Duplex are increasingly being used for longer service life under tougher conditions.