Strong wastewater sorting proves vital for rule following and running smoothness. Yet, usual sorting ways like hole-punched boards or net covers often face regular blocks, steep upkeep fees, and poor stream. For current wastewater handling sites, stainless steel wedge wire screens bring a tech-better answer. They provide dependability, long life, and a much smaller full owning cost. This guide will lead you through why these screens stand as the field norm. Plus, it shows how to pick the correct one for your wants.

Why Wedge Wire Screens Excel in Wastewater Filtration

The outstanding running of these screens comes from their special build.

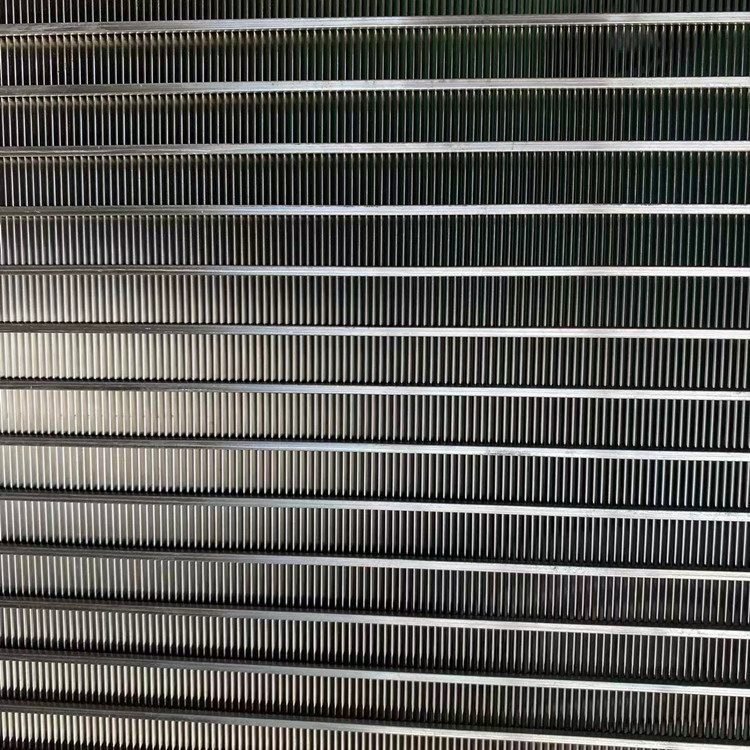

The Non-Clogging Advantage of the V-Shaped Profile

Wedge wire screens are built from V-shaped profile wires that join to backing bars. This setup makes a gap that stays tight on the outer side and grows inside. Any bit that goes through the exact outer hole will keep moving without sticking. This built-in block-proof trait sharply cuts stop time. It also lessens the call for regular back rinsing or hand scrubbing.

Superior Hydraulic Performance and Efficiency

The ongoing, steady gaps offer a huge open spot. This often beats that of net or hole-punched boards by a lot. Such a thing lets greater stream speeds with little force drop over the screen top. In wastewater tasks, this means you can handle a larger amount with finer power use.

Unmatched Durability for Harsh Environments

Wastewater acts as a rough and eroding setting. Stainless steel wedge wire screens are made for this test. The joined build forms a firm, stiff, single-unit shape that can handle high forces and tough working states. As a result, it guarantees a lengthy and steady service span.

Key Factors for Selecting the Right Screen

Picking the proper screen calls for thinking about several main points.

Slot Size

The slot size ranks as the top detail. It must stay small to grab the aimed solids. But it needs to grow big for the best stream. A sharp slot size secures steady and dependable split running. Such a thing proves key for hitting release rules.

Material Grade

While stainless steel fights rust by nature, various levels (such as 304 or 316L) give changing guards against certain chemicals and salts in factory or city wastewater. Choosing the right level matters a lot for extending the screen’s lasting time.

Screen Construction

Wedge wire screens do not fit all cases. They appear in diverse shapes for separate steps of the handling process. Usual kinds include:

• Drum wire screens: Used in turning screen setups for first handling and sludge packing.

• Wedge Wire Curved Screens: Fit for still, pull-fed split of solids from liquid flows.

• Wedge Wire Screens: Used for continuous separation and filtration in liquid–solid processing.

Jingzhou: Your Partner for High-Performance Filtration Solutions

Grasping these basics marks the first move. The next involves teaming with a maker who can fulfill them.

Decades of Expertise in Wedge Wire Manufacturing

Since we began in 2009, Jingzhou has centered on the study, growth, and production of stainless steel metal wires. We hold skill in both the raw Wedge wire and the finished Wedge wire screen/filter items used in factory sorting. This deep know-how lets us manage the level from the very start of the steps.

Unmatched Customization for Your Specific Needs

We grasp that every wastewater flow holds unique traits. For this reason, our top strength rests in supplying items “customized according to customers’ needs”. Our own study skills and Mold Development know-how mean we can build a screen with the precise slot size, material level, and build your task calls for. You might need a basic Screen cylinder or a tricky Conveyor belt screen. In either case, we can create it.

A Commitment to Quality You Can Measure

We pledge to supply “the best cost-effective products” without cutting corners. Our making steps are backed by strict level control. We employ a 2D Measuring Projector for the High-precision detection of slot sizes and shapes. Moreover, every item goes through the required Tensile Testing as part of our last check before sending. Such a step promises to build wholeness.

Conclusion

Picking the correct wedge wire screen acts as a stake in the long-term running and stability of your wastewater handling work. By teaming with Jingzhou, you gain access to better solutions, sharp buildings, and fully made-to-order answers planned to run in the toughest states.

Reach out to us now to gain the backing and answers you require for your sorting task.

FAQ

Q: What makes wedge wire screens better than perforated plates for wastewater?

A: The V-shaped profile of wedge wire creates a non-clogging surface, leading to less maintenance and more consistent flow. Perforated holes can easily clog with fibrous or irregular solids common in wastewater.

Q: Can Jingzhou produce a screen for my specific wastewater composition?

A: Yes. This is our specialty. With our R&D Capability and Mold Development, we can create a fully customized screen with the ideal material grade and slot size to match your specific filtration requirements.

Q: What types of wedge wire screen products does Jingzhou offer?

A: We offer a comprehensive range, including Drum wire screens, Wedge Wire Curved Screens, Sieve plates, Screen cylinders, Candle filters, and more.