Key Factors in Selecting Eyeglass Frame Wire

Comfort, Flexibility, and Skin Compatibility

Comfort is essential when picking eyeglass frame wire. The material must bend easily to match facial contours. It should hold its form without creating uncomfortable pressure. Skin safety matters greatly because the wire touches skin for long periods. Hypoallergenic qualities prevent reactions, especially for delicate users.

Durability and Resistance to Deformation

Eyewear endures daily use and occasional accidents. Frame wire must withstand bending while keeping structural soundness over the years. High tensile strength stops frames from losing shape or snapping under strain.

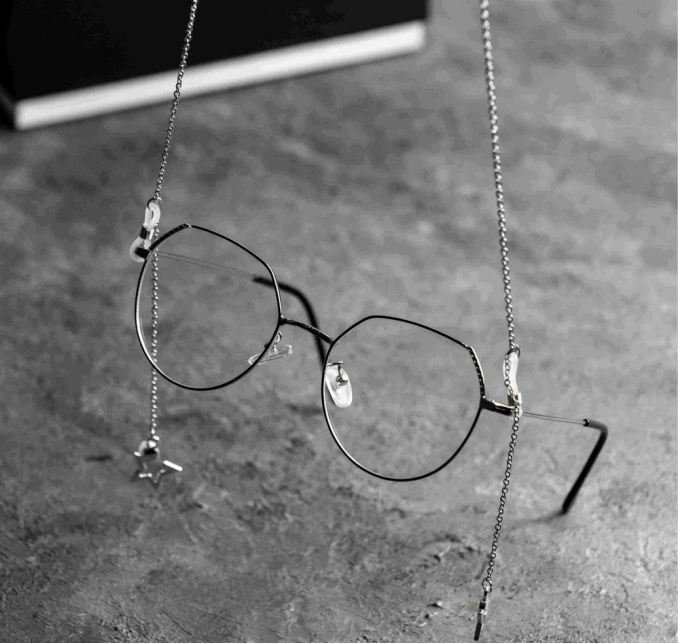

Corrosion Resistance and Surface Finish

Glasses encounter sweat, dampness, and outdoor elements. Corrosion protection is vital. A sleek finish improves visual charm and wearer comfort by minimizing skin friction.

Jingzhou’s Stainless Steel Wire Advantages

Jingzhou has focused on stainless steel wire since 2009. Through constant quality dedication, Jingzhou holds ISO9001 certification and national high-tech status. Our custom profile wire leads industry standards. We deliver tailored frame wire solutions meeting exact needs for hardness, thickness, and surface treatment. We prioritize client satisfaction, offering personalized services for diverse product demands.

Comparing Common Eyeglass Frame Wire Materials

Stainless Steel vs Titanium: Pros and Cons

Titanium is feather-light and fights corrosion superbly, perfect for high-end frames. However, it costs more and resists shaping due to its stiffness. Stainless steel balances economy and function. It delivers reliable strength, manageable weight, easy forming, and solid everyday rust protection.

Why Stainless Steel Remains a Popular Choice

Grades 304 and 316L stay dominant for their anti-corrosion traits and value. Stainless steel forms into extremely fine wires with tight accuracy. This suits detailed eyewear needing complex bends without sacrificing resilience or comfort.

Product Highlights from Jingzhou

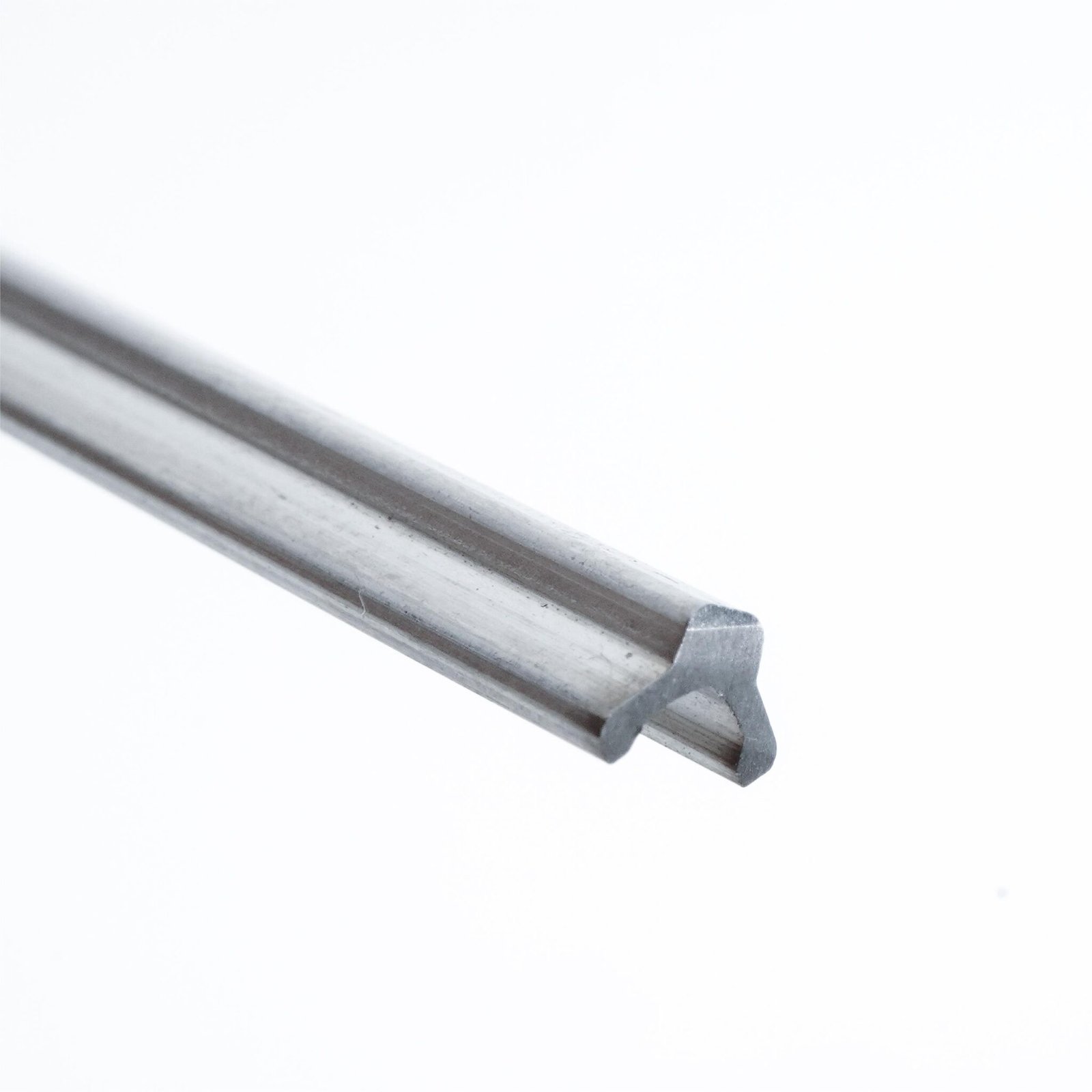

Jingzhou SUS304 – Precision Wire for Comfort Fit Frames

Jingzhou’s SUS304 stainless wire combines dependable toughness with superb bendability. It’s ideal for frames needing frequent adjustments without cracking. Cold drawing refines its diameter, boosting precision and resilience. This suits comfort-focused designs where adaptability equals sturdiness. Our fine drawing yields a silky finish. This reduces skin discomfort while elevating visual quality.

Jingzhou SUS316L – Corrosion-Resistant Option for Outdoor Use

SUS316L stainless steel excels in wet or harsh settings due to superior rust resistance. Annealing eases internal strain and renews malleability. Fine drawing ensures exact sizes and sleek surfaces. This grade fits sports eyewear or sunglasses used near oceans or humid zones where salt damages weaker metals rapidly.

Practical Tips for Eyewear Manufacturers

Choosing the Right Diameter and Hardness Level

Thickness depends on frame style. Thicker wires add stiffness while slender ones enable intricate shapes or folding designs. Match hardness to application: Softer wires ease assembly bending; harder grades maintain structure under pressure.

Jingzhou supports OEM/ODM work with trial runs and bulk orders from blueprints. This ensures perfect design alignment.

Surface Treatment Options: Polished, Coated, or Matte Finish

Surface finishes affect both looks and feel:

- Polished gives a glossy shine

- Coatings enable color choices

- Matte cuts glare in bright light

Jingzhou customizes finishes to client specs. This helps brands stand out visually while boosting comfort. Contact us now via email jing@jingzhoumetal.com for more information.

FAQ

Q: Which metal works best for eyeglass frame wires?

A: Stainless steel leads for balanced strength, flexibility, corrosion defense, and cost efficiency.

Q: Can Jingzhou make custom frame wires?

A: Yes. We provide tailored solutions for unique diameters, hardness levels, shapes, and surface finishes.

Q: How does Jingzhou maintain quality?

A: We use infrared gauges for size consistency, spectrometers for material checks, and tension testers for strength verification. All under strict ISO9001 controls.

Q: What finishes are typical for frame wires?

A: Standard options include polished (shiny), matte (low-gloss), and coated (colored). Jingzhou produces any finish per design needs.