Understanding Wedge Wire Screens

What Is a Wedge Wire Screen

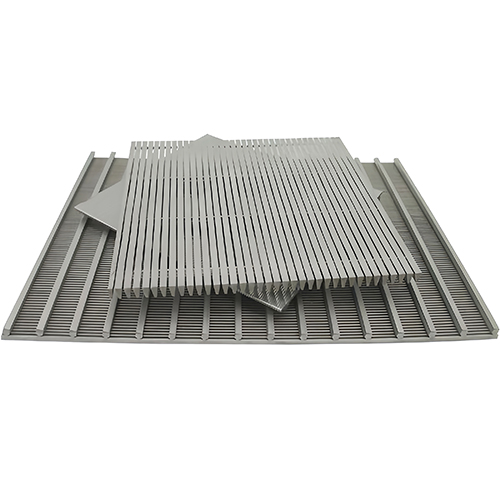

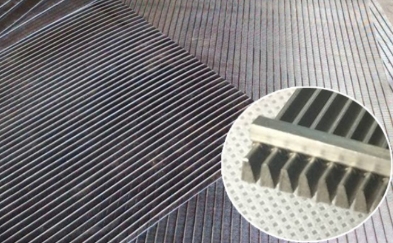

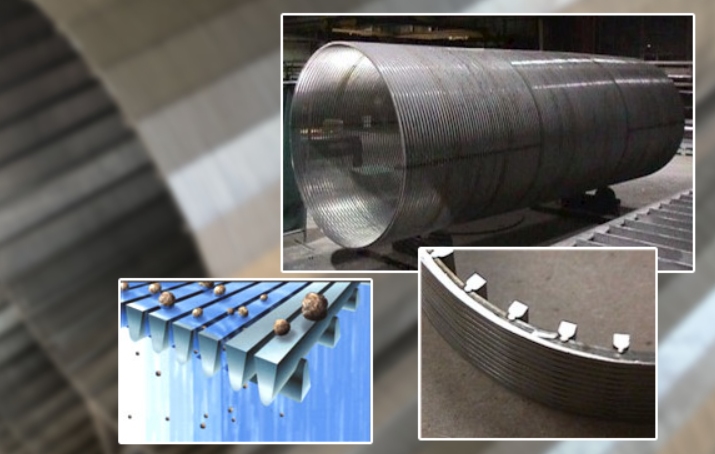

A wedge wire screen is a type of filter made from stainless steel wires. These wires are formed into a V-shape and then welded onto support rods. People also refer to it as profile wire or V-wire. This design is known for being strong, durable, and resistant to corrosion. The structure provides continuous slot openings. These slots allow for very accurate filtration while keeping the screen sturdy.

Key Benefits of Using Wedge Wire Screens

The special wedge shape offers many useful advantages. Important features include high strength and solid structure. They also resist corrosion and heat very well. The slot openings are precise, which helps achieve better filtration. Additionally, the V-shape helps the screen clean itself. This makes these screens perfect for uses that need a steady flow, minimal clogging, and a long lifespan.

Key Factors When Selecting a Screen

Slot Size and Open Area Considerations

Slot size affects which particles the screen can hold back. Smaller slots provide finer filtration. However, they might lower the flow rate if the open area is not well balanced. Our experts can help you choose the best setup for your process.

Flow Rate and Pressure Requirements

Systems work under different flow and pressure conditions. Our wedge wire screens are built to stay stable even under high pressure. This is because of their welded design and strong materials.

Material Compatibility and Corrosion Resistance

Picking the right material is very important when working with harsh chemicals or saltwater. Stainless steel types 304 and 316L are popular due to their good corrosion resistance and reasonable cost. For even tougher conditions, we also provide Duplex or Super Duplex alloys.

Common Applications of Jingzhou Screens

Water Treatment and Filtration Systems

This field uses stainless steel filters for treating drinking water, wastewater, and seawater. You will find our wedge wire screens in intake systems, sand filters, and desalination plants. They are also used in other water cleaning units.

Food and Beverage Processing Equipment

They are used for filtering drinks like beer, wine, and fruit juices. They help remove unwanted particles such as yeast, bacteria, and sediment. Our stainless steel screens have a clean design that meets food safety rules. They are also easy to clean.

Mining, Chemical, and Petrochemical Industries

Wedge wire is used in refining to filter out impurities from crude oil. This makes it very important in petrochemical work. In mining, our screens are used for jobs like slurry separation or dewatering. They give reliable results with little upkeep.

Tips for Maintain Wedge Wire Screen

To get the best performance and longevity from your screen, proper installation and maintenance are essential. Here are some tips to ensure success.

Correct installation

Correct installation helps your screen last longer and work better. Make sure it is aligned properly. Also, avoid putting too much stress on the welded joints by using good support structures.

Cleaning Methods to Extend Service Life

Cleaning your screen regularly helps avoid clogging and keeps the flow efficient. Depending on where it is used, you can clean it by backflushing with water or using mild chemicals.

When Jingzhou screens are installed and maintained well, they deliver measurable system efficiency improvements. Here’s how our products support your operation.

The V-shape helps stop particles from getting stuck in the slots. This self-cleaning effect happens during operation. Therefore, you will need less manual cleaning and have less downtime.

Reduced Downtime Due to High Durability

We maintain strict quality control through a series of advanced inspections, including tensile testing, spectrometer analysis, and infrared measurement. As a result, our products deliver reliable long-term performance and rarely require replacement.

Here’s how each technique contributes:

- Infrared Detector: Monitors and minimizes dimensional variations across each coil.

- Spectrometer Analysis: Accurately verifies material composition.

- Tensile Force Meter: Measures the maximum tensile strength to ensure structural integrity.

Why Choose Jingzhou Wedge Wire Screens

Precision Slot Control for Accurate Filtration

At Jingzhou, we focus on making wedge wire screens with very precise slot sizes and tight tolerances. Our wedge wire screens, including water well screens, have a strong build and a high open area. This means they separate solids from liquids or gases accurately. As a result, your filtration system becomes more efficient.

Durable Stainless Steel for Long-Term Use

We produce our wedge wire screens from good quality stainless steel like 304 or 316L. They are very resistant to corrosion and wear very slowly because of this. Stainless steel wire is widely employed for industrial filtration for its hardness as well as resistance to wear. Even when put under harsh conditions, it does not get damaged. That is why our screens work well under harsh conditions like petrochemical plants and water treatment plants.

Conclusion

Jingzhou’s custom wedge wire screens mix precise engineering with top-quality materials. They serve many industries, from water treatment to food processing to petrochemicals. We offer tailored answers supported by technical knowledge and worldwide service. We help you get the best filtration performance with fewer operational breaks.

FAQ

Q: What makes wedge wire screens better than traditional mesh filters?

A: Wedge wire screens have exact slot openings. These allow accurate filtering and reduce clogging thanks to the self-cleaning V-shape.

Q: Are Jingzhou’s wedge wire screens suitable for corrosive environments?

A: Definitely. We use high-grade stainless steels such as 304 and 316L. We also offer Duplex alloys for better corrosion resistance in tough conditions like seawater or chemical exposure.

Q: How long do your wedge wire screens typically last?

A: With correct setup and care—like regular backflushing or chemical cleaning—our sturdy stainless-steel screens last a long time, even with constant use.