Common Clogging Issues in Water Treatment

Clogging remains an ongoing problem in water treatment systems. Sediments, biological matter, and industrial waste particles frequently build up on filtration components. This buildup causes lower flow rates, greater pressure loss, and repeated maintenance breaks. As a result, it raises running costs. It also harms the quality of treated water. Standard mesh filters or perforated plates often catch debris in hard-to-clean spots. This speeds up wear and lowers system performance.

Why Choose Wedge Wire Screens

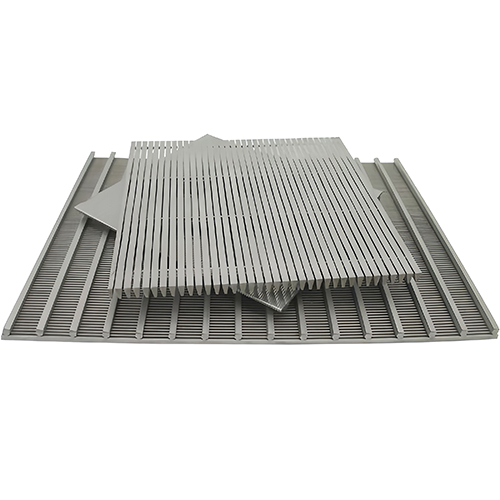

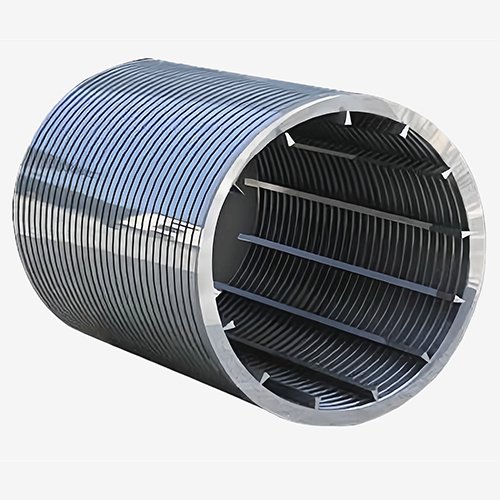

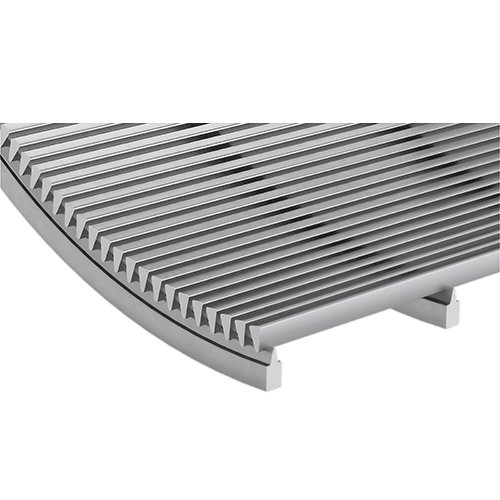

Wedge wire screens offer a better answer to these issues because of their build and material traits. Stainless steel wedge wire, also known as profile wire or V-wire, is a kind of wire shaped in a V-form or triangular section. This special shape gives self-cleaning abilities. Particles do not stick easily in the screen gaps. The exact slot openings permit fine filtration accuracy. At the same time, they keep firm mechanical stability under changing pressures.

Wedge wire mesh is recognized for its toughness, solid strength, and ability to resist corrosion. These qualities make wedge wire screens suitable for extended use in tough settings like wastewater treatment plants and seawater desalination sites.

Jingzhou Wedge Wire Screen Features

Jingzhou focuses on making high-performance stainless steel wedge wire screens designed for industrial filtration demands. A stainless steel wedge-welded wire screen (water well screen) consists of warp rods and wires. The warp wires are triangular (V-shaped), providing a precise slot size. This ensures effective separation of solids from liquids.

Wedge wire screen (water well screen) has the characteristics of corrosion resistance, safety and reliability, good heat resistance, good mechanical properties and long service life. Jingzhou improves product dependability through strict quality checks. They use spectrometer analysis for alloy confirmation, tensile force meters for strength evaluation, and projectors for size accuracy.

Key Product Models from Jingzhou

Jingzhou provides a wide variety of wedge wire screen models, including:

- Screen Panel

- Screen cylinder

- Custom Shapes: Including trapezoidal or round rods based on application needs.

We support OEM/ODM services, long-term partnerships, and custom production based on drawings or specifications. All products can be customized with different slot widths, diameters, lengths, and end fittings according to customer requirements.

Applications Across Water Treatment Scenarios

The flexibility of wedge wire screens lets them work in many stages of water treatment:

- Intake Filtration: Stops debris from reaching pumps.

- Sand Filters: Take out suspended solids before further treatment.

- Wastewater Clarification: Divides sludge from treated water.

- Ultrapure Water Systems: Applied in semiconductor industries needing exact filtration.

They are commonly used in fields such as water treatment, oil and gas, mining, food processing, and pulp and paper.

Installation and Maintenance Tips

Correct installation guarantees the top performance of wedge wire screens:

- Make sure of proper alignment with the flow direction.

- Apply suitable gaskets or seals to stop bypass leakage.

- Check slot openings regularly for wear or shape changes.

Due to their self-cleaning form and strong build, wedge-shaped openings allow the fluid to flow efficiently while effectively filtering solids. This reduces maintenance needs when compared to regular filters.

How Jingzhou Enhances Efficiency and Durability

Jingzhou’s making process involves cold drawing for size precision. It includes annealing to ease internal stress. Then comes the shaped rolling into V-wire profiles. Finally, fine drawing handles tight tolerances. These actions make sure products follow strict industrial rules.

Our independently developed stainless steel profile wire is always ahead of the industry. Additionally, Jingzhou Metal Products has passed the ISO9001 quality system certification. This ensures steady quality in every batch.

Customer Support and Customization Services

At Jingzhou, we stick to the idea of serving customers well. We offer optional customized services based on the product needs of different customers.

Our team provides:

- Technical consultation

- Rapid prototyping

- OEM/ODM cooperation

- Flexible order quantities

- Timely after-sales response within 24 hours

We also give shipping choices, including sea freight, air freight, or express delivery via DHL/FedEx, depending on urgency.

FAQ

Q: What makes wedge wire screens better than traditional mesh filters?

A: Wedge-shaped openings are formed between the V-shaped wires, which help maintain flow efficiency while reducing clogging risks due to their self-cleaning design.

Q: Can I request customized dimensions or slot sizes?

A: Yes, at Jingzhou Metal, we provide customization services. We can design and manufacture stainless steel profile wires to meet specific application requirements, including different wire diameters, opening sizes, and overall dimensions.

Q: How long does it take for delivery after placing an order?

A: Generally, it is 7–15 days if the goods are in stock, or it is 10–20 days if the goods are not in stock, depending on quantity.