In tough industrial settings, the material’s reliability remains essential. You might design intricate filtration setups or create accurate parts. Yet, ordinary wire frequently falls short in toughness and exactness. The answer comes from cold-drawn wire. This substance gets improved via modern creation methods. As a result, it satisfies rigid performance needs.

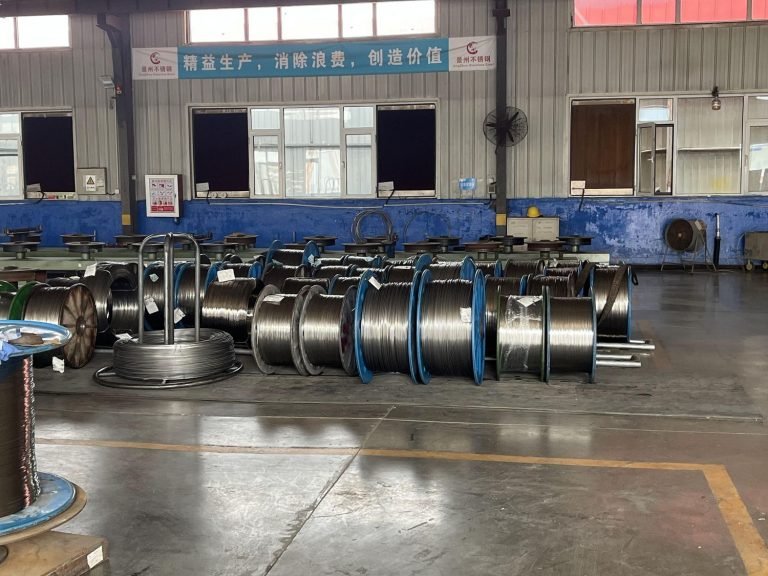

We are Jingzhou, a dedicated R&D and output firm for stainless steel metal wires since our start in 2009. Our ongoing emphasis and current production gear have set our stainless steel shaped wire and round wire in a top spot within the field. For knowledgeable purchasers, a solid grasp of the cold drawing method proves vital. It helps them reach smart buying choices.

The Foundation of High-Performance Wire

Cold-drawn wire acts as the core element for many top-notch items across advanced areas and tasks that demand materials that fit tight rules. This approach changes a simple wire rod into a unique stock. Consequently, it gains better features needed for key parts.

Defining the Foundation: What is Cold-Drawn Steel Wire?

The Mechanism: Enhancing Strength and Smoothness

Cold drawing involves reworking and stretching rolled steel wires. It applies to both low and high carbon steels. The procedure happens at normal temperature. It pulls the wire rod through smaller and smaller molds, which shrinks its width. This physical step boosts the substance’s firmness, yield power, and pull strength. Additionally, it creates a much better outer quality than hot rolling.

Jingzhou’s Manufacturing Process for Cold-Drawn Wire

Jingzhou maintains steady standards through a managed, multi-phase item procedure:

1. Wire Rod: The raw substance in coil shape is ready.

2. Cold-Drawn Round Wire: The wire rod undergoes drawing to cut its width. This action boosts size, correctness, and power.

3. Round Wire Annealing: This eases inner tension and brings back bendability to the drawn wire.

4. Shaped Rolling: The wire takes on the needed tailored forms, like flat, square, trapezoidal, or V-shapes.

5. Fine Drawing: This last phase secures narrow limits, exact sizes, and a sleek outer finish.

Understanding Cold-Drawn Wire’s Superiority

Cold-Drawn Wire’s Properties

Cold drawing adds several wanted traits:

• High Mechanical Strength: The method leads to strong yield powers, pull strength, and firmness.

• Enhanced Elastic Limits: After proper handling or cold drawing toughening, the wire shows a strong elastic boundary and weariness boundary.

• Dimensional Accuracy: The drawing and fine drawing phases confirm exact sizes and sticking to rigid limit levels.

• Superior Surface Finish: Cold-drawn steel wire holds a finer outer finish than hot-rolled steel.

Cold-Drawn Wire Advantages

The outcome benefits render cold-drawn wire suitable for intricate industrial requests:

• Boosted mechanical traits, which supply strong yield powers, pull strength, and firmness.

• Better outer handling, which cuts the call for extra outer handling and raises the end standard.

• Permits quicker cutting speed.

• Quicker reply to ball-forming with better shaping ability.

• Can be made in the desired width span.

• Provides strong power, framework stability, and fine rust and warmth protection (especially stainless steel kinds).

Real-World Application and Strategic Customization

Cold-Drawn Wire Industrial Applications

The adaptability and top standard of cold drawn wire allow its role across a broad span of fields.

• Filtration and Separation: Jingzhou’s Wedge Wire (V-shaped/triangular wire) stems directly from this method. It helps make sturdy Wedge Wire Screens/Filters. These find wide use in industrial filtration, water handling, oil and gas, and mining. The reason lies in their strong power and rust protection.

• Component Manufacturing: Cold-drawn wire appears in car parts (like brake springs) and farm gear (like framework parts and rake teeth).

• Specialized Wires: Jingzhou creates assorted Irregular-Shaped Wires such as T-shaped, V-shaped, and eyeglass frame wire. These serve industrial filtration, medical tools, and jewelry adornment. We also make SS Y Zipper wire for upscale metal zipper teeth.

Strategic Customized Flexibility

We see that many tasks need custom materials. Thus, Jingzhou supplies optional tailored services based on certain item needs. We back-tailor samples and produce custom output grounded strictly on client sketches or details. This versatility, linked with R&D skills that cover Mold Development, confirms that we supply accurately fitted wire forms. These match narrow limits. Our ISO9001 approval and standard checks—including Spectrometer Analysis, Infrared Detector, and 1D/2D Measuring Projectors—assure that each tailored answer fits the needed level. This happens before sending via Tensile Testing.

Conclusion: Partnering for Reliable Wire Excellence

Picking Jingzhou signifies choosing better cold-drawn wire items supported by technical know-how and a constant search for standards. Reach out to us today. You can gain the exact, economical, tailored wire answers that your key tasks require.

FAQ

Q: What is the main objective of the cold drawing process?

A: The main objective is to achieve better durability, strength, flexibility, and a smooth outer surface compared to hot-rolled wire.

Q: How does Jingzhou ensure the dimensional accuracy of its cold-drawn wire?

A: We use an Infrared Detector to monitor dimensional variation and 1D and 2D Measuring Projectors to inspect critical dimensions and tolerances.

Q: Can Jingzhou manufacture non-standard wire profiles using cold drawing?

A: Yes, we specialize in producing various stainless steel special-shaped wires and support custom production based on specific customer drawings or specifications.

Q: In which key industries are Jingzhou’s cold-drawn drawn shaped wires used?

A: They are widely used in industrial filtration, oil and gas, medical devices, and high-end apparel (e.g., zipper wire).