Need a filtration solution that lasts longer, works better, and saves money? Discover why stainless steel wedge wire is revolutionizing industries—from water treatment to food processing—and how Jingzhou’s precision engineering delivers unbeatable performance. Read on to find your perfect filter match!

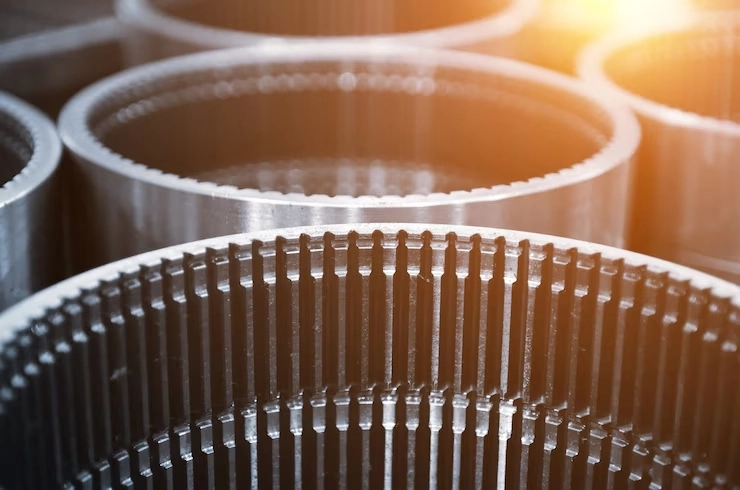

Why Pick Stainless Steel Wedge Wire?

The material you choose matters a lot for how long your filter lasts.

Corrosion-Resistant Performance

304/316 stainless steel wedge wires resist rust in saltwater and chemicals, perfect for marine and chemical applications.

Durable & Low-Maintenance

Hard-wearing 400-series stainless steel wires endure harsh conditions with minimal replacement, reducing long-term costs.

Good for the Planet

Stainless steel is 100% recyclable. Using stainless steel wedge wires helps the environment by cutting down waste.

Why Stainless Steel Is a Win

It’s tough, long-lasting, and green, making it perfect for filters that need to work hard and stay eco-friendly.

Where Do People Use Wedge Wire?

1. Mining industry: Wedge wire screen panels for mineral separation

2. Water well drilling: Precision well screens for groundwater extraction

3. Petroleum sector: Filter tubes for oilfield applications

4. Wastewater treatment: Corrosion-resistant curved screens and filter tubes (including chemical filtration processes)

What Should You Think About When Picking Wedge Wire?

Choosing the right wedge wire means knowing what your system needs.

Gap Size and Flow Needs

Every job needs a different filter level. Picking the right gap size keeps filtering spot-on without slowing down flow.

Material Choices for Special Jobs

For example, titanium is great for aerospace because it’s light. Our main products include special-shaped wires of different materials (stainless steel, copper, titanium). But stainless steel is the top pick for most jobs because it’s cheap and works great.

Custom Options for Unique Tasks

Some jobs need special fixes. Specializing in the production of various stainless steel special-shaped wires: V-shaped wire…, makers like Jingzhou can tweak sizes like height, width, or even support rods to fit your needs.

Why These Choices Matter

Getting the right gap, material, and custom fit makes your filter work perfectly for your job.

How Does Jingzhou Make Great Wedge Wire?

As more folks need trusty filters for water, oil, mining, or food jobs, makers like Jingzhou step up with awesome products.

Trusty Stainless Steel Wire Maker

Since 2009, Tianjin Jingzhou Metal Products Co., Ltd. has worked hard on making and selling stainless steel wires. They know their stuff, making wire wrapped screens for filters in tons of industries.

Super Exact Making

Jingzhou’s own stainless steel profile wire is top-notch. They use cool tools like spectrometers, tensile testers, infrared detectors, and mold fixers to make sure every batch meets global rules for size and quality.

Focus on Quality and Happy Customers

Jingzhou cares about making customers happy. They offer custom services to fit different needs. Whether you want special sizes or big orders fast, Jingzhou delivers trusty products worldwide.

Why Jingzhou Is Awesome

Jingzhou’s know-how and great products make them a go-to for awesome wire wrapped screens.

Conclusion

Stainless steel wedge wire delivers durable, precise, and eco-friendly filtration. Jingzhou’s expertise since 2009 ensures high-quality, customizable solutions for diverse industries. The right material, gap size, and design optimize performance, making it the smart choice for efficient, long-lasting filtration systems.

FAQ:Are There Green Benefits to Stainless Steel Wedge Wires?

Yes! Stainless steel is fully recyclable, cutting waste while keeping top performance. Our main products include… ultra-fine wires… supporting sustainable practices.