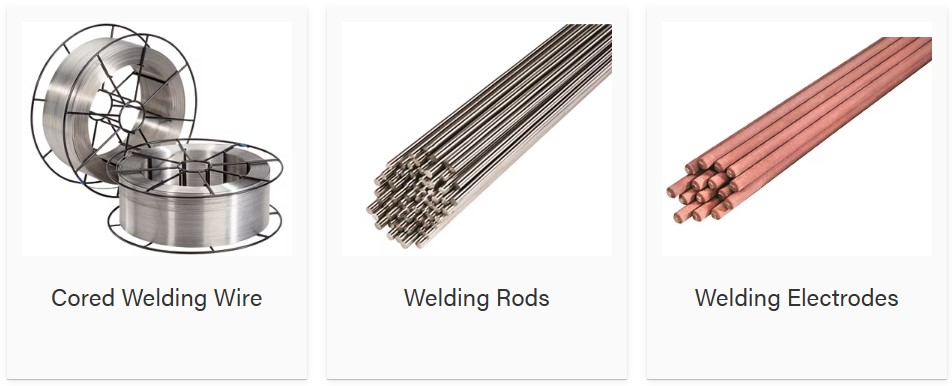

Flux core welding wire is a common technique in industrial applications requiring a strong, high-quality weld. This welding technique uses a flux core, a hollow wire filled with a flux material that helps shield the weld pool from contaminants and oxidation. Flux core welding wire is an excellent choice for fabrication applications because it is more affordable and faster than other welding techniques, such as TIG and MIG welding.

Flux Core Welding Wire is a versatile and efficient welding material with a hollow core filled with flux, eliminating the need for external shielding gas. It offers excellent weld quality, strong arc stability, and enhanced performance in outdoor and windy conditions.

This welding wire provides superior penetration, reduced spatter, and high deposition rates, ensuring consistent and clean welds. It is suitable for welding thick materials, offers easy slag removal, and performs well in challenging environments, making it ideal for both professional and DIY use.

Flux Core Welding Wire is widely used in construction, shipbuilding, automotive repair, and heavy equipment fabrication. It is suitable for welding structural steel, mild steel, and other metals in outdoor or poorly ventilated settings.

There are two types of flux-cored wire electrodes: gas-shielded and self-shielded.

Gas-Shielded Flux-Cored Wire: Requires external shielding gas, ideal for high-strength and precision welding in controlled environments.

Self-Shielded Flux-Cored Wire: Generates its own shielding gas, perfect for outdoor and windy conditions without additional equipment.

Welding rods and electrodes are essential tools for fusing metals, providing a consistent arc and reliable bonding in welding processes.

Deliver high-strength welds, excellent arc stability, minimal spatter, and compatibility with diverse materials and environments.

Widely used in construction, manufacturing, automotive repair, pipeline welding, and maintenance to join metals, repair damage, and enhance wear resistance.

Welding Rods & Electrodes Welding Processes

- Shielded Metal Arc Welding (SMAW): Commonly known as stick welding, uses flux-coated rods for various applications.

- Gas Tungsten Arc Welding (GTAW): Also called TIG welding, involves non-consumable electrodes for precision work.

- Gas Metal Arc Welding (GMAW): Known as MIG welding, utilizes consumable electrodes with shielding gas for fast, clean welds.

- Flux-Cored Arc Welding (FCAW): Uses flux-cored electrodes for efficient welding in outdoor or windy conditions.

- Submerged Arc Welding (SAW): Employs a continuously fed electrode under a blanket of flux for heavy-duty welding.