Screen Support Wire

Structural Features: We use high-quality stainless steel (304, 316L) or high-strength alloy to make the support rod. This material offers corrosion resistance, high-temperature resistance, and wear resistance, making it suitable for working environments like mining and oil and gas. We can customize the support rod with round, trapezoidal, rectangular, or special-shaped sections based on different working conditions. This customization ensures precise matching with the wedge wire winding and enhances the stability and durability of the overall screen.

Function: The support rod is the key load-bearing component of the Wedge Wire Screen. It is mainly used to fix the wedge wire winding to ensure uniform gaps and a firm structure. At the same time, it determines the flow direction of the fluid and optimizes the filtration efficiency. The precision welding process firmly welds the support rod to the wire winding, so that the screen has a higher pressure bearing capacity and is suitable for high-intensity filtration environments.

Application areas: Widely used in water treatment, oil well filtration, petrochemical separation, food and pharmaceutical, mining screening, papermaking and environmental protection industries, suitable for deep well filters, rotary screens, drum screens, pressure screens and other equipment, providing efficient, stable and durable support solutions.

Product Parameters

| Material | 202B 304 304L 316 316L 316Ti 321 430 8825 809C E300, etc. |

| Specification | 0.5*1.0mm-8*10mm |

| Dimensions Tolerance | +/-0.01mm |

| Production Capacity | 1200ton/month |

| Package | Wooden spool/Steel spool |

| Shape | As required |

| Application | filtration industrial |

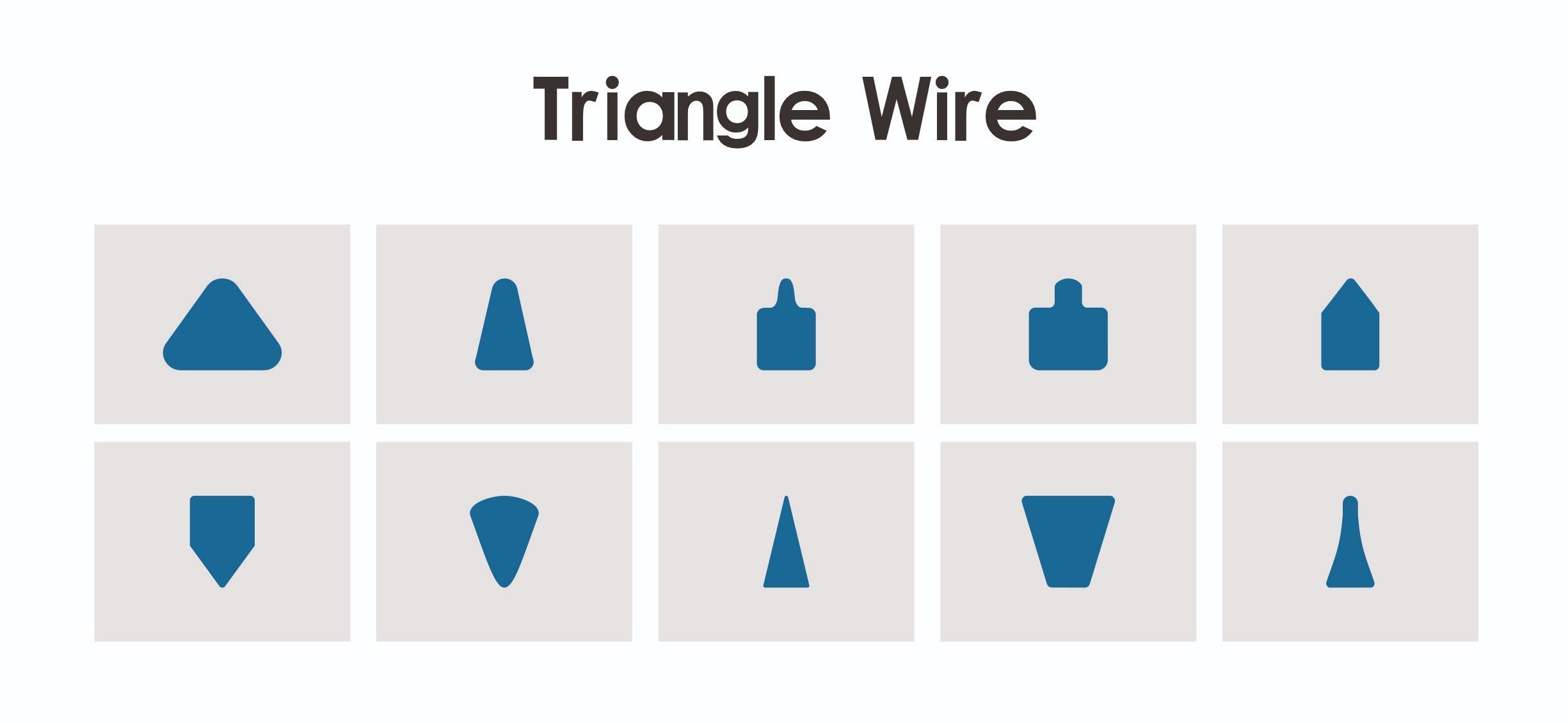

Available Types

Drawing

Production Process

Package