In tough factory tasks, gear work depends on the stuff used to make it. For sorting and dividing setups, the way to better output and long life rests in one special part: wedge wire. This goes beyond basic wire. Its exact V-shaped side sets it as the base for top sorting parts in the field. Jingzhou, a committed maker with a focus on R&D and building stainless steel metal wires since 2009, knows that top work starts with well-planned wire.

Top 10 Benefits Enabled by Precision Wedge Wire

1. Minimized Clogging and Improved Filtration Efficiency

The V-shape marks wedge wire. In a full setup, it forms a gap that widens inward. This odd form makes sure bits touch at just two spots. As a result, it cuts the chance of blocks a lot. And it lets work run steadily and well.

2. Unmatched Strength and Durability

When wedge wire joins to hold frames, it shapes one very solid piece. The built-in power of the wire matters most. At Jingzhou, we promise this body soundness by doing strict Tensile Testing on our stainless steel wire before shipping out. This way, it holds big pushes and heavy weights.

3. Precise Slot Size Control

The rightness of a sorting part hangs on even gaps and holes. Such exactness works only if the wedge wire is made to tight size limits. Jingzhou draws on exact check gear, like a 2D Measuring Projector. These tools make sure each bit of wire fits your wants.

4. Ease of Cleaning and Maintenance

Items from good wedge wire show a flat, ongoing top. This plan lacks the cracks in wedge wire screen. So, it allows simple and good washing by ways like back flush. In turn, this drops stop time and fixes costs.

5. Increased Flow Rates with Low Pressure Drop

The high power-to-size link of well-made wedge wire lets us build parts with maximum open space. This brings more flow speed and a small push fall. And it raises power savings for your whole setup.

6. Enhanced Resistance to Wear and Corrosion

Jingzhou focuses on building wedge wire from top stainless steel. This stuff gives strong fight to rust, hot spots, and scrapes. So, it ensures long run time even in the roughest factory states.

7. Essential for Guarding Food Safety

The clean traits of stainless steel wedge wire fit the food and drink field. The smooth surface fights germ pile and adds no taste. This keeps goods pure and safe.

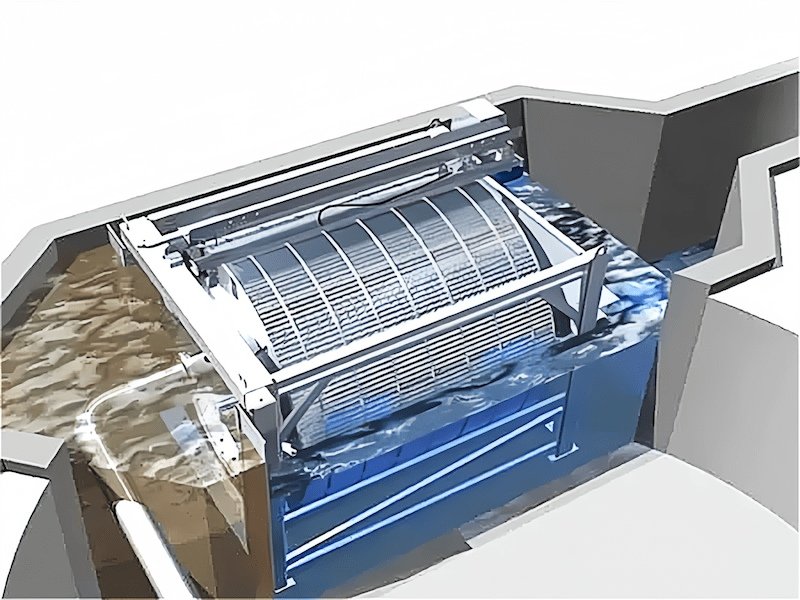

8. A Key Role in Advanced Water Treatment

From pull-in builds to hold media, the trust in water clean setups relies on no-block and long-lasting traits of inner parts. All these come from the main wedge wire tech.

9. Versatility in Architectural Applications

Past factory sorting, the neat look and frame power of wedge wire make it a liked stuff for building covers, fronts, and pretty parts. This points to its great fit in many ways.

10. The Power of Customized Solutions

The top gain of wedge wire lies in its changeability. At Jingzhou, we do well in giving made-to-fit wire choices. Our own R&D Capability and Mold Development know-how let us build made-to-fit wedge wire and odd-shaped wires. We match the right side, size, and stuff your task needs.

Jingzhou: Your Partner for Customized Wedge Wire

Since 2009, Jingzhou has led in R&D and the building of stainless steel-shaped wire. We center on giving buyers the top value items. We do this by using new build tools and close checks on quality. If you want a basic side or a full-made-to-fit wedge wire, our group commits to planning the right base stuff for your top-work task.

Conclusion

The great wins of new sorting and dividing tech all start with one base part: good wedge wire. By picking a build team set on exactness, quality, and made-to-fit, you make sure your end product delivers the work you vow.

Contact Jingzhou today to talk about your made-to-fit wedge wire wants. And find out how our know-how can lift your goods.

FAQ

Q: What materials does Jingzhou use for wedge wire?

A: We specialize in high-quality stainless steel, which offers excellent durability and corrosion resistance. As part of our customized manufacturing service, we can discuss other alloys, such as titanium wire, to meet the specific demands of your application.

Q: Can Jingzhou create a unique wedge wire profile for my product?

A: Absolutely. We specialize in customized solutions. Our dedicated R&D team and in-house Mold Development capabilities allow us to engineer wedge wire and irregularly shaped wires precisely to your specifications.

Q: How does Jingzhou guarantee the quality of its wedge wire?

A: We employ a strict quality control process, using high-precision detection tools like a 2D Measuring Projector for dimensional accuracy and conducting Tensile Testing before shipment to verify mechanical strength and durability.