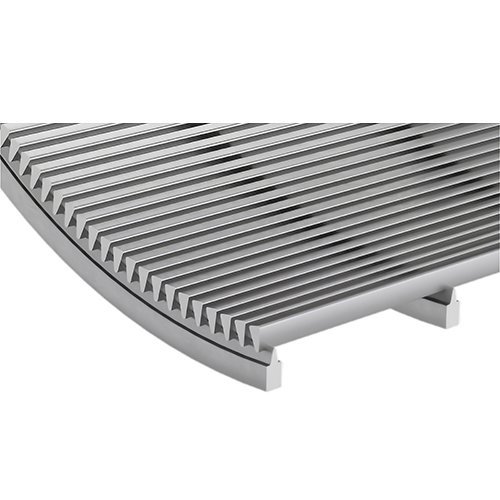

In tough factory fields around the globe, keeping filtration and separation steps working well and steady is very important. Usual screens often break down under strong push, rust, and scrapes. And this leads to big losses in time and money. Wedge wire screens stand out in these spots. Built for power and solid output, their special V-shaped wire setup gives a better choice. Jingzhou, a focused maker with strong R&D and making of stainless steel metal wires since 2009, sends this new tech to many places across the world.

Critical Applications Across Key Industries

The Oil and Gas Industry

In rough spots for oil and gas pulling out and cleaning up, gear breaks are not okay. Wedge wire screens give the needed toughness for key tasks.

Applications & Benefits: They help with sand hold in deep wells, keeping catalysts in reaction units, and sorting. These screens face huge push and bad mixes. The fully joined build of wedge wire ensures great physical power. At Jingzhou, we check this toughness with strict Tensile Testing before each send-off. This way, our items meet the field’s top rules.

Water Treatment and Environmental Engineering

For city and factory water setups, holding high flow speeds while getting exact sorting is the main goal. Wedge wire tech sets the way for good and long-term work.

Applications & Benefits: From big water pull-in screens in streams to small-gap screen tubes in clean units, wedge wire offers a no-block top with lots of open space. So, it cuts push drop and power use. Jingzhou uses exact check tools, like our 2D Measuring Projector. These help make sure each gap fits the right size. In turn, this brings a steady hold on bits.

Mining and Metallurgical Applications

The mining field wears gear down fast. Screens need to take steady scrapes from heavy, pointy stuff. And they must do key sizing and water removal jobs.

Applications & Benefits: Wedge wire screens fit this hard work. Their strong, all-joined build fights wear much better than woven nets. Items like thick drum wire screens and sort plates help split rocks and pull water from the mix. Their power means a long run time, even in the worst spots.

The Food and Beverage Industry

Clean, item wholeness, and good speed top the list in food and drink handling. The setup of wedge wire screens fits these wants just right.

Applications & Benefits: The even, no-crack top of stainless steel wedge wire cleans easily and fights germ build. This makes it great for steps like pulling juice from fruit, making beer, and splitting solids. The no-block V-shaped gaps keep work going without stops.Jingzhou can provide customized screen services for this industry.

Jingzhou: Your Partner for Customized Engineering

Basic screens fill some wants, but real betterment comes from a choice built for one process. This idea sits at the heart of Jingzhou’s way. We focus on fully made-to-fit wedge wire screen/filter items. Our strong R&D Capability and our own Mold Development let us team with clients. Together, we plan and build the right screen for their task. This works if it needs the usual shapes or hard, odd-shaped wire. We promise to bring the top value items. And we do this without cutting into build or output.

Conclusion: The Clear Choice for Demanding Applications

The wide fit and strong build of wedge wire screens turn them into a must-have tool in many key fields. To use these gains fully, teaming with a build pro is key.

Contact Jingzhou today to talk about your made-to-fit job wants. And let us build the right wedge wire choice for your task.

FAQ

Q: What makes wedge wire screens so durable?

A: we select corrosion-resistant stainless steel grades that maintain structural integrity under extreme conditions. Each batch undergoes spectrometer verification to ensure material composition meets strict standards, guaranteeing long-term performance in demanding applications.

Q: Can Jingzhou create a screen for our company’s unique equipment?

A: Yes, for sure. We focus on made-to-fit choices. Our R&D Capability and our own Mold Development let us plan and build wedge wire screens/filters to your exact wants. This makes sure a good match for any gear.

Q: How does Jingzhou ensure the slot size is accurate?

A: We use exact check gear, like a 2D Measuring Projector. This checks all sizes, plus the key gap openings. They fit the buyer’s right needs. So, sorting stays steady and sure.