In the current challenging industrial setting, the output of each part counts. From complex electronics to big construction tasks, the selection of material can decide between victory and defeat. Cold-rolled flat wire shines as a flexible and strong-performing material. China has become a worldwide center for its creation. As a committed maker since 2009, Jingzhou leads this field. It focuses on the study, growth, and making of top-quality stainless steel wires. This overview will look into the gains, applications, and production of cold-rolled flat wire. It will demonstrate why it serves as the better option for your upcoming task.

What is Cold Rolled Flat Wire?

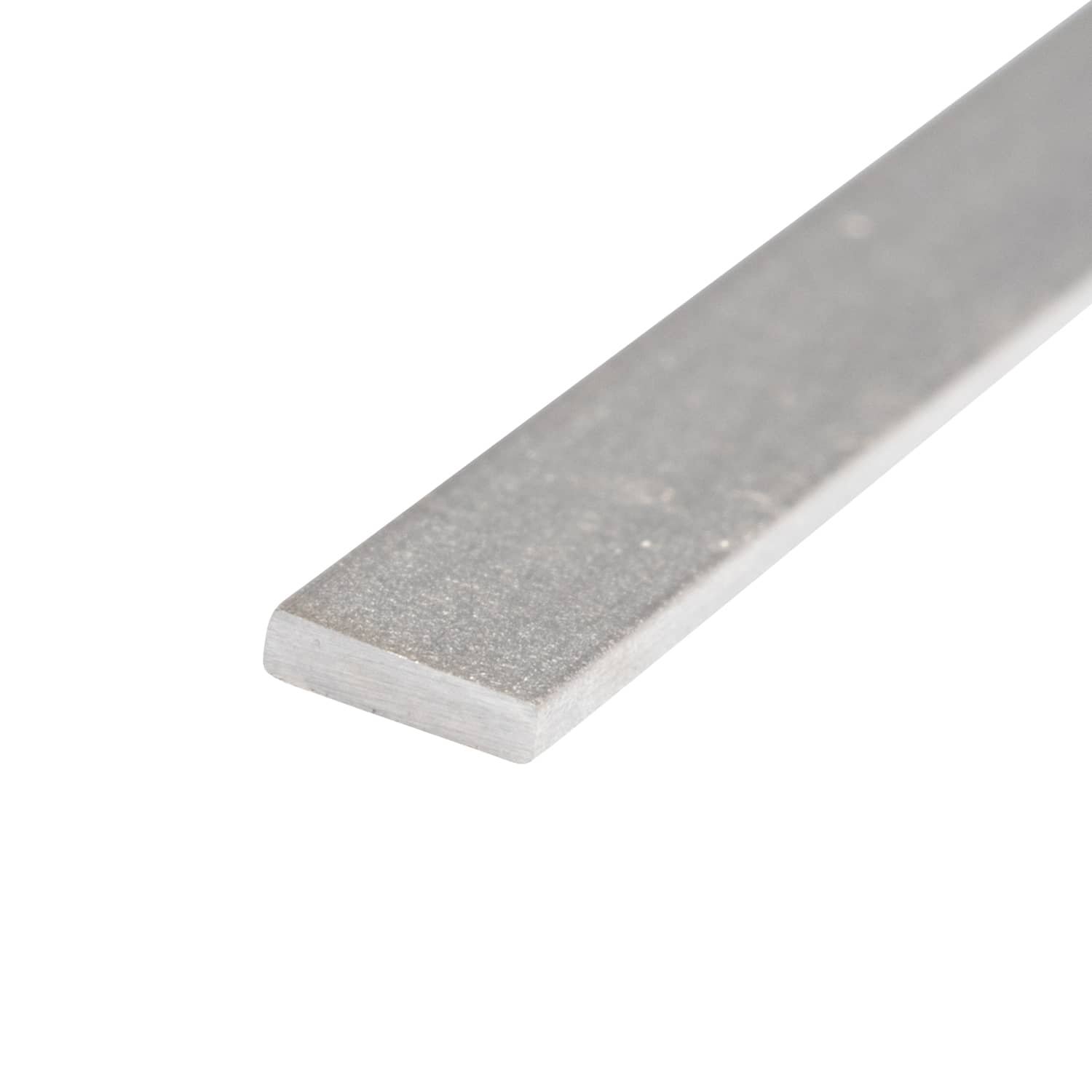

Cold-rolled flat wire is a special item created by altering usual round wire into a flat, rectangular form. This step happens without warmth (cold rolling). Such a method toughens the steel and greatly boosts its mechanical features and outer finish. The outcome is a wire that proves tougher and more exact than its starting shape.

Key Characteristics

Jingzhou’s stainless steel flat wire is built for quality. It provides a distinct mix of traits:

• Better Strength and Toughness: The cold-rolling method adds great power. This makes it dependable in tough surroundings.

• Strong Corrosion Resistance: Crafted from top stainless steel types like SS304 and SS316, our flat wire stands up well against rust and wear in rough settings.

• Exact Sizes: We reach very close size limits of up to +/-0.01mm. This guarantees evenness and steadiness for accurate uses.

• Clean, Nice Surface: The creation process leads to a neat and even surface. It suits tasks where looks matter.

• Simple Shaping: Our flat wire is straightforward to form, join, and build. This gives broad options in planning.

Benefits of Cold-Rolled Flat Wire in Construction

The special traits of cold-rolled flat wire turn into major pluses for the building sector.

While the sources point out its role in electronics, car parts, and health tools, its features prove very helpful for building. Details on certain building uses below do not come from the given sources. They might need separate checking.

• Improved Structure Strength: Its high power-to-weight balance makes it suitable for strengthening parts and holds without extra weight.

• Lasting Life and Little Upkeep: The fine corrosion resistance of stainless steel ensures that items from our flat wire handle weather and outside contact for many years.

• Design Freedom: The even surface and ease of forming let builders and planners craft fresh, sharp lines for trim details, outer covers, and inner parts.

Uses of Cold-Rolled Flat Wire in Construction

Based on its features, cold-rolled flat wire fits a broad scope of building tasks. Once more, these exact roles do not appear in the sources. Yet, they stand as reasonable expansions of the material’s skills. These can cover:

• Hold parts in hanging roofs and wall setups.

• Strong ties and holders.

• Design mesh and trim grids.

• Items for window and door borders.

• Coils and machine parts inside the structure gear.

Manufacturing Process of Cold-Rolled Flat Wire in China

- Wire Rod:Wire rod is the raw material in coil form, serving as the base for further processing.

- Cold Drawn Round Wire:The wire rod is cold drawn through dies to reduce diameter and improve dimensional accuracy and strength.

- Round Wire Annealing:Annealing relieves internal stress and restores ductility to the cold-drawn wire.

- Shaped Rolling:Shaped rolling forms the round wire into customized profiles such as flat, square, or trapezoidal shapes.

- Annealing:A second annealing process softens the shaped wire and removes internal stress.

- Fine Drawing:Fine drawing ensures tight tolerances, precise dimensions, and smooth surface finish.

- Packaging:Packaging is done based on customer requirements, ensuring safe handling, transport, and storage.

Why Choose Chinese-Made Cold Rolled Flat Wire from Jingzhou

When you team up with Jingzhou, you pick a maker, not a sales firm. This straight link offers big pluses:

Top Customization

We focus on tailored answers. At Jingzhou, buyers will customize items right from our plant. We can plan and create stainless steel profile wires to fit your exact task needs. This includes various sizes and forms. Whether you require flat, many-sided, or Y-shaped wire, we hold the skill to supply.

Guaranteed Standard

With more than ten years of know-how and a pledge to R&D, we promise items that reach the top levels of standard and accuracy. You can inspect all in our plant and feel sure of the item standard.

Steady Supply Line

Our large output ability and quick processes ensure a firm supply for tasks of any size. We also provide clear delivery schedules.

Conclusion

Cold-rolled flat wire brings a fine blend of power, toughness, and accuracy. This makes it a key material across many fields. As a top Chinese maker, Jingzhou supplies not only an item, but a team. We mix top-quality supplies with solid know-how and fully customized services. In this way, we deliver the precise answer you require.

Ready to begin your next task with better flat wire? Ask for a price now or reach out to us to talk about your customized needs.

FAQ

Q: Are you a trading company or manufacturer?

A: We are a factory. Customers will customize products from our company and can check the quality on-site.

Q: Is it possible to customize stainless steel profile wires?

A: Yes, at Jingzhou, we provide customized services. We design and manufacture stainless steel profile wires to meet specific application requirements.

Q: Do you provide samples?

A: Our company will decide whether to provide samples based on the quantity of customized steel wire you order. For large orders, we can provide samples for free.