In the key area of wastewater handling, speed and dependability stand as essential. Separating solids from liquids well presents an ongoing issue. This problem can affect many things. It touches on running costs and rules for the environment. Luckily, a fresh and very tough answer is available: the wedge wire curved screen. This method gives a better way for solid-liquid division. As a top make, Jingzhou commits to creating strong screens adjusted to your exact needs.

Fundamentals of Wedge Wire Curved Screen

Design and Mechanics

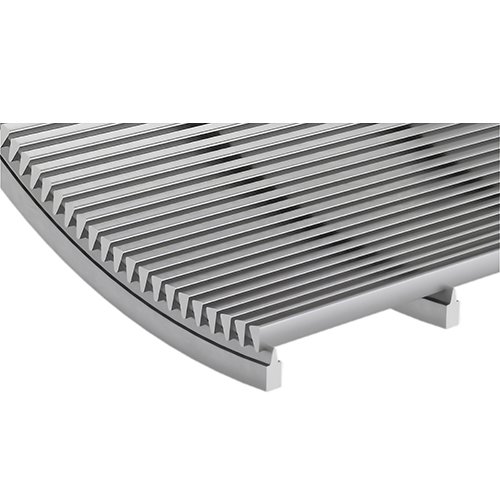

The wedge wire curved screen shows a wonder of basic yet useful building. It gets made by winding and joining V-shaped stainless steel profile wires around hold bars. This forms an even screen face with steady, non-blocking gaps. The V-shaped form makes sure that as bits move through, the gap grows inward. Such a setup stops any solids from sticking. It also promises a steady flow and reliable well output. The screen’s side and upright power are built to avoid curving and keep exact gap correctness, even with heavy weights.

Screen Curvature

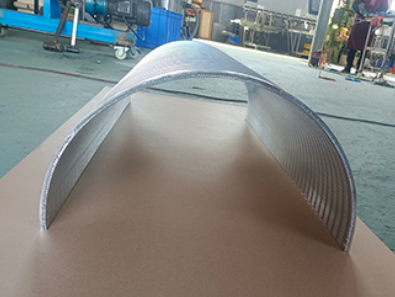

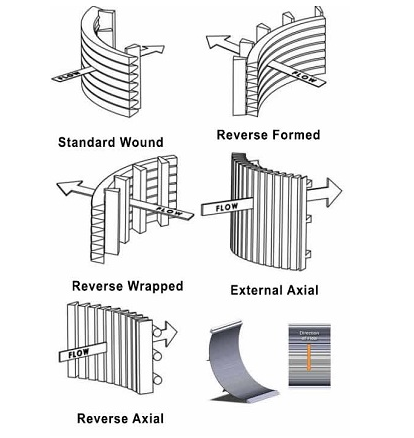

Also called DSM screens or arc screens, these units show a clear inward bend. This bent build is a main plus. It provides much improved filtering speed and a larger handling ability compared to flat screen boards. Jingzhou creates screens in a broad range of bends, including usual kinds like 45°, 60°, 120°, and 300°. This allows for tuned output.

Flow Dynamics

When wastewater moves over the bent face, the special water movement cuts away slim layers of water through the screen’s V-shaped gaps. This step, paired with the screen’s bend, speeds up the water removal process. It also boosts division speed.

Materials and Fabrication

Toughness begins with top supplies. At Jingzhou, we build our wedge wire screens from fine stainless steel types, including SS304, SS304L, SS316, and SS316L. This choice promises great resistance to rust and a lengthy working span. The end item can come without a frame or with a customized frame to fit your setup needs. All our items require customization for creation and handling to make sure they match your precise details.

Application in Wastewater Management

Solids Separation

The main role is quick solid-liquid division. These screens are well-suited for taking out floating solids from different wastewater flows. This includes streams from washing places, food making, and fish farming tasks.

Preliminary Treatment Processes

In city and work settings, these screens act as a vital first phase in the handling chain. They get used for early water removal, dirt clearing, and sorting of supplies in coal-ready plants, mineral handling spots, and sewage cleaning systems.

Operating Parameters

Throughput Capacity

Due to their bent design and non-blocking gaps, wedge wire screens provide quite a high filtering ability. This makes them fit for tough, high-flow tasks.

Screen Aperture Size

Exact filtering is central to good handling. Jingzhou supplies screens with gap sizes from 20μm to 3000μm, with a fine limit of ±5μm. This permits better sand handling, which can cut upkeep on pumps. In the end, it lengthens the span of the well or system.

Inclination and Flow Rate

The screen’s bend, or arc, can be customized to tune output for certain flow speeds and supply kinds. Usual bends range from 90° to 160° and more. This secures an ideal fit for any process.

Maintenance and Cleaning

Manual and Automated Methods

One of the largest pluses of the V-shaped wire design is the small upkeep needed. The non-blocking gaps clean themselves to a great extent. This sharply lowers stop time and the work linked to clearing blocked screens.

Screen Wear and Tear

Over time, rough supplies will lead to damage to the screen’s face. This can widen the opening size. The sources point out that screens with a smaller opening bend face a slower rise in gap size. Such a trait helps to stretch the total working span of the unit.

Market Trends and Future Outlook

Industrial Demand

The need for quick and tough water handling methods remains high across many sectors. This covers mineral handling, paper creation, and sewage cleaning. The flexibility of the wedge wire curved screen places it as a central part in these fields.

Research and Development

Since our start in 2009, Jingzhou has focused on the study and growth of stainless steel metal wires. This pledge makes sure we stay at the lead of creation methods. We get driven by the customized needs of our clients and the changing calls of work filtering.

Why Choose Jingzhou?

When you team up with Jingzhou, you select a maker, not a sales firm. This straight link gives big pluses. We offer fully customized services. We plan and create stainless steel profile wires and screens to fit your exact task needs. This includes various wire widths, opening sizes, and total measures. As a plant, we welcome you to “check everything and rest assured of the quality of the products”. Our solid background and emphasis on R&D promise items that reach the top levels of standard and exactness.

Ready to improve your wastewater handling process? Ask for a price from Jingzhou today. Let our specialists assist you in planning the ideal customized screen answer.

FAQ

Q: Are you a trading company or manufacturer?

A: We are a factory. Customers will customize products from our company. In our factory, you can check everything and rest assured of the quality of the products.

Q: Is it possible to customize stainless steel profile wires according to customer specifications?

A: Yes, at Jingzhou, we provide customized services. We can design and manufacture stainless steel profile wires to meet specific application requirements, including different wire diameters, opening sizes, and overall dimensions.

Q: Do you provide samples?

A: Our company will decide whether to provide samples according to the quantity of steel wire customized by you. If the quantity is large, we will provide samples for free.