In the world of industrial manufacturing, few materials are as versatile yet overlooked as the humble stainless steel wire. From the massive sieve bends used in deep-earth mining to the microscopic needles used in life-saving surgeries, this material is the silent backbone of global progress. At Jingzhou, we have spent over 15 years perfecting the R&D and production of these essential metal wires. Since 2009, we have pushed the boundaries of what a single strand of metal can achieve, proving that with the right engineering, one product can truly serve many worlds.

The Core of Industrial Efficiency: Wedge Wire in Mining and Filtration

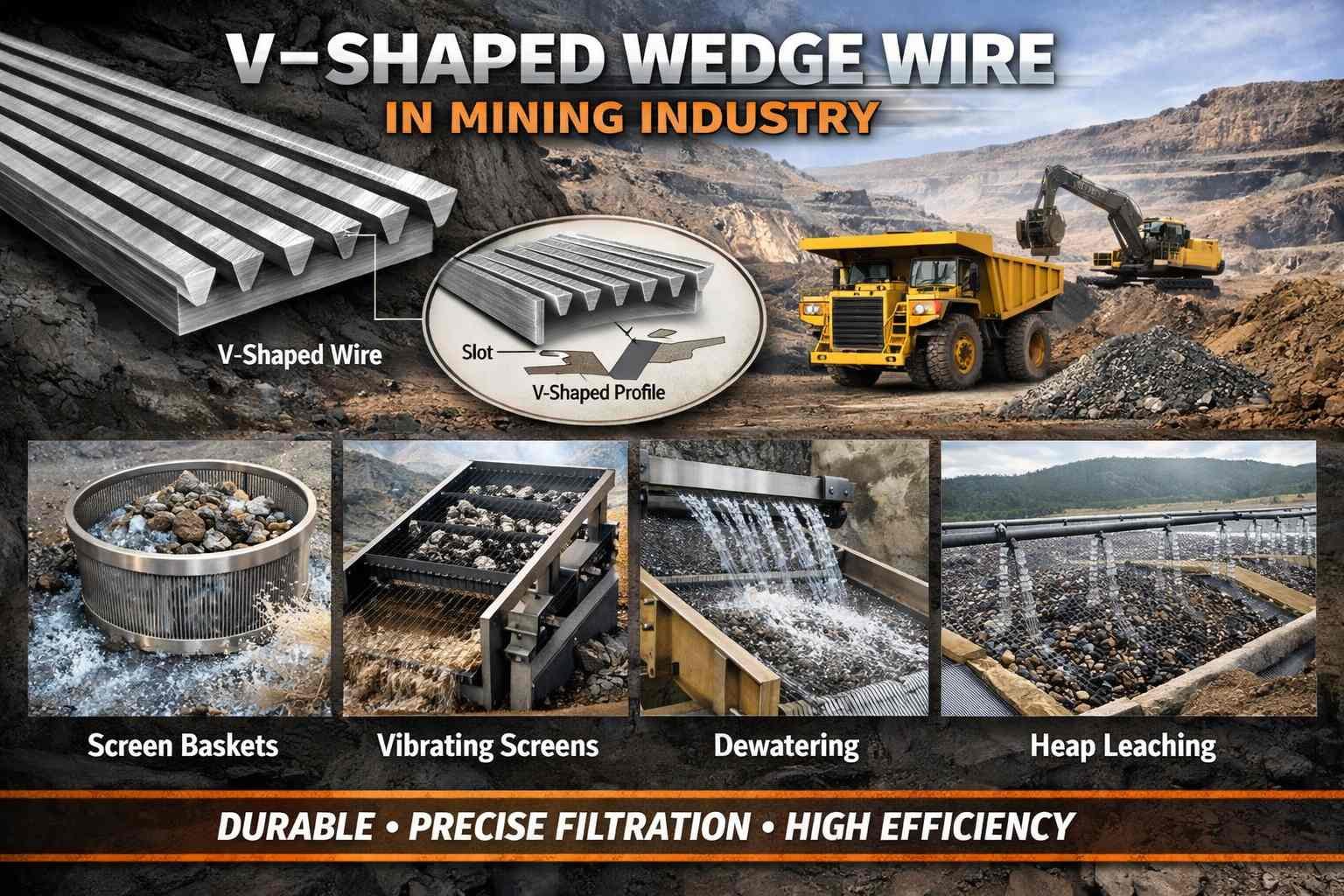

For industries dealing with heavy-duty filtration, efficiency is measured by the ability to separate solids from liquids without interruption. This is where Jingzhou’s Wedge wire—also known as V-shaped wire—becomes indispensable.

Precision and Power in Solid-Liquid Separation

Our Wedge wire screen is engineered by welding V-shaped profile wires onto support rods, creating a slot that enlarges inwardly. This unique geometry offers a customized advantage: it is inherently clog-resistant. While traditional mesh might trap particles, our V-shape allows “fines” to pass through easily, ensuring a continuous flow and reducing maintenance costs.

Case Study: Optimizing Coal and Mineral Processing

In mining environments, our Wedge Wire Curved Screens (DSM screens) are a game-changer. These screens are used for preliminary dewatering and classification of materials like coal. Because the material flows over a curved surface, the filtration efficiency is significantly higher than that of flat screens, allowing mining operators to achieve greater capacity with a more compact footprint.

Precision Where It Matters Most: Medical Grade Solutions

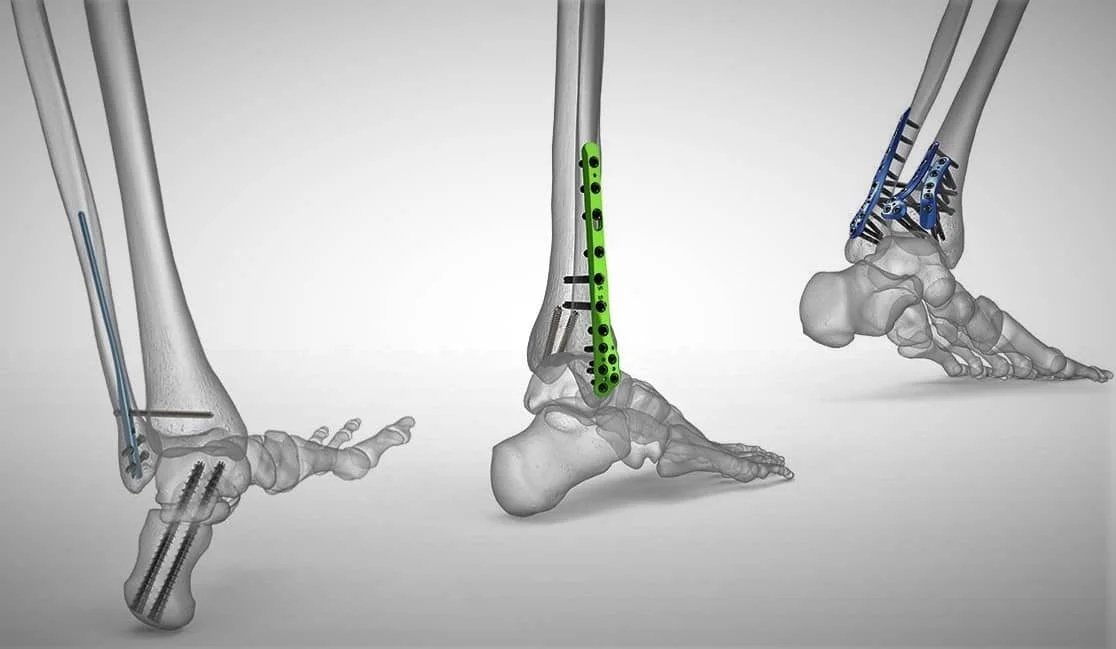

Moving from the rugged environment of a mine to the sterile precision of an operating room, the requirements for stainless steel wire shift from raw strength to biocompatibility and extreme tolerance control.

Biocompatibility and Reliability

Jingzhou specializes in Round wire and Titanium wire crafted from high-grade 316L stainless steel and medical-grade titanium. These materials are chosen for their exceptional corrosion resistance and ability to withstand repeated sterilization without degrading.

Advanced Applications: Surgical Instruments and Orthopedic Implants

Our customized wires are used to manufacture surgical tools such as forceps and scalpel handles, where precision is paramount. Furthermore, our Titanium wire is a preferred solution for orthopedic implants, including bone plates and screws. Its non-toxic nature and high strength-to-weight ratio ensure that it performs reliably within the human body without causing adverse reactions.

Versatility in Form: From Jewelry to High-Fashion Accessories

Beyond heavy industry and healthcare, stainless steel wire adds a touch of modern sophistication to the world of design.

Aesthetic Durability for Artistic Designs

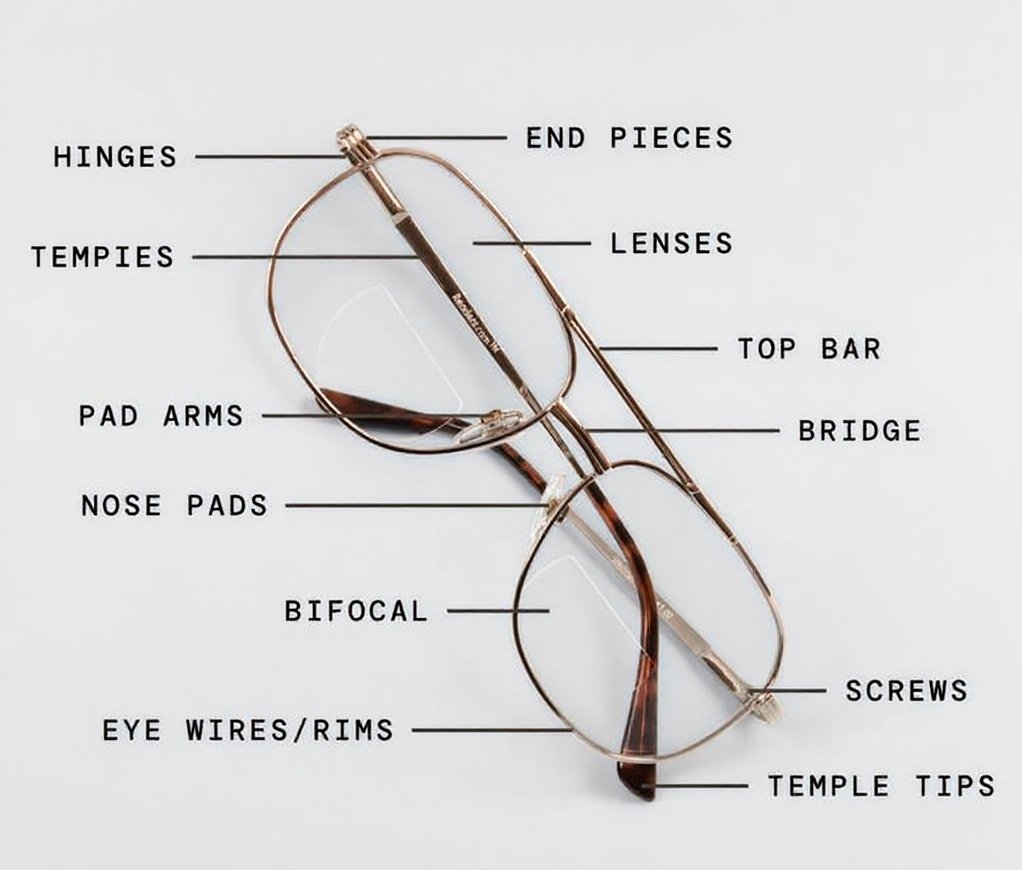

Jewelry makers and fashion designers leverage our Irregular-profile wire and Fine round wire for its sleek, modern look that won’t tarnish over time. Whether used in the intricate weaving of a necklace or as structural components in high-end handbags, our wire provides the flexibility needed for artistic expression and the durability required for daily wear. For the eyewear industry, we provide customized eyeglass frame wire that maintains its shape and resists skin-acid corrosion.

Why Jingzhou is the Global Choice for Customized Wire

What sets Jingzhou apart in this cross-industry storytelling is our commitment to a customized service model. We understand that a “standard” wire does not exist in a world of complex engineering.

Unmatched R&D and Quality Control

Spanning 18,000 square meters across three production bases, our facilities are equipped with industry-leading testing equipment. We utilize infrared detectors to monitor dimensional variation across every coil and 2D measuring projectors to ensure that every customized order meets strict quality control limits.

The Power of a Customized Solution

Whether you require a specific relief angle for a Wedge wire profile, a unique slot opening down to 20μm, or a specific alloy for aerospace applications, we provide the solution. At Jingzhou, we don’t just sell wire; we design and manufacture customized stainless steel profiles to meet your exact application requirements, ensuring optimal performance from the very first day.

Conclusion: Partnering for Cross-Industry Innovation

From the depths of a mine to the precision of a surgeon’s hand, Jingzhou stainless steel wire is there. Our journey since 2009 has been one of continuous innovation and dedication to our partners across the globe. We invite you to experience the reliability and precision that thousands of international clients already trust.

Ready to elevate your project with the perfect wire solution?

Contact Jingzhou today to discuss your customized requirements.

- Email: jing@jingzhoumetal.com

- WhatsApp/Wechat: +86 15320163118

- Website: Visit us (www.jingzhoumetal.com) to explore our full product manual.

FAQ

Q: In what applications is stainless steel wedge wire mainly used?

A: It has been widely used in mining processes, water treatment, and industry for effective solid-liquid separation and anti-clogging.

Q: Why is stainless steel wire preferred for use in the medical field?

A: Medical stainless steel and titanium wires are biocompatible and resist corrosion and the effects of repeated sterilizations.

Q: Is the stainless steel wire customizable for industrial applications?

A: Yes, there is a customization possible regarding wire diameter, shape, slot size, as well as alloys.

Q: What kind of applications do fine and irregular profile wires have in the industry?

A: Fine and irregular profile wires may be used for jewelry, optical, and other applications