In today’s heavy industry settings, one weak part can shut down operations for days. That means big repair bills and lost production time. Sectors like aerospace, chemical plants, and offshore rigs deal with harsh saltwater, acids, or blazing heat that chew through regular steel fast—often in just a few weeks. That’s where titanium steps in. Jingzhou, as a key producer, supplies tough metal wires built to last in spots where ordinary ones give out quick.

The Science of Resilience: Why Titanium Dominates

Titanium beats steel not just in terms of weight. It stays solid under brutal conditions. Right away in the air, it grows a tough oxide skin that blocks most attacks from water, salts, or chemicals. This layer heals itself if scratched, so the wire keeps working without pitting or thinning out over time.

Unrivaled Corrosion Resistance in Chemical and Marine Settings

Titanium wire stands out for shrugging off rust and enduring tough surroundings. Saltwater sprays or full immersion wreck carbon steel screens in ocean rigs within months. Titanium holds up fine, year after year. Chemical refineries push crude oil through pipes hit with sulfur fumes and nitrogen compounds at high pressure. Standard alloys crack under stress or pit from the acids. Jingzhou’s titanium wires keep surfaces smooth. Filtration meshes and support frames run for years without leaks. Technicians report pulling old coils from marine pumps after a decade, and they look nearly new—no flaking or weak spots.

High-Temperature Stability for Aerospace and Automotive Success

Heat hits metals hard. Most soften above 500°C, lose shape, or burn up. Titanium mixes like those with vanadium or aluminum hold firm past 600°C. Strength per pound stays high, even after hours at red-hot levels. Aircraft engines spin at 1,000°C in spots; titanium wire weaves into turbine blades and exhaust frames. One missed flight from a failed part costs airlines $50,000 an hour. Rockets blast off with titanium supports that take the thermal shock without warping. Auto race teams fit it in exhaust valves and brake lines. Vibration shakes loose weaker wires after 10,000 miles; titanium endures 50,000 miles with no creep or fatigue cracks.

Jingzhou’s Precision Engineering: Our Titanium Product Portfolio

At Jingzhou, we know top materials come from tight control in the mill. From 2009 on, our Tianjin plant has shaped metal profile wires for demanding jobs. Modern rolling lines and heat treatments hit specs that high-tech buyers demand, like zero defects per 1,000 meters.

Technical Specifications and Material Excellence

Jingzhou makes pure titanium grades plus strong alloys. Monthly output hits 1200 tons, enough for mega bridge cables or small satellite parts.

- Specifications: Wire sizes run from φ0.8mm to φ6.0mm.

- Precision: Tolerances sit at +/-0.01mm, so wires slot perfectly into tight machine slots.

- Surface Quality: Bright polish on every spool, packed on wood or steel reels to avoid scratches in shipping.

Advanced Customized Solutions for Specific Industrial Needs

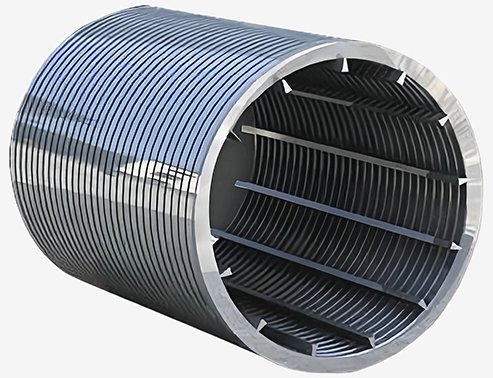

No two jobs match. Jingzhou shapes wires beyond round—V-profile, triangle, or odd forms for screens and hooks. Send a sketch with diameter needs, slot widths for filters, or alloy picks for body-safe uses. Our shop crew runs trial rolls, tests pulls up to 1,200 MPa, then scales to full batches. A wedge wire screen for acid tanks might call for 1.5mm thick triangles with 0.5mm gaps; we nail it in 15 days. Medical grades get extra clean for implant weaving, holding shape at body temps for 15 years.

Global Applications: Where Jingzhou Titanium Wire Performs

Jingzhou wire shows up worldwide, from Gulf oil fields to Brazilian ships. It fits tight, where weight cuts fuel 20% and downtime drops to near zero.

Aerospace and Automotive Engineering

Satellites orbit with Jingzhou wire in antenna frames—light enough for launch, strong for solar flares. Planes use it in wing fasteners that flex in turbulence. Cars pack it in turbo housings; engines hit 800°C bursts, and the wire clamps without melting after 100,000 km road tests.

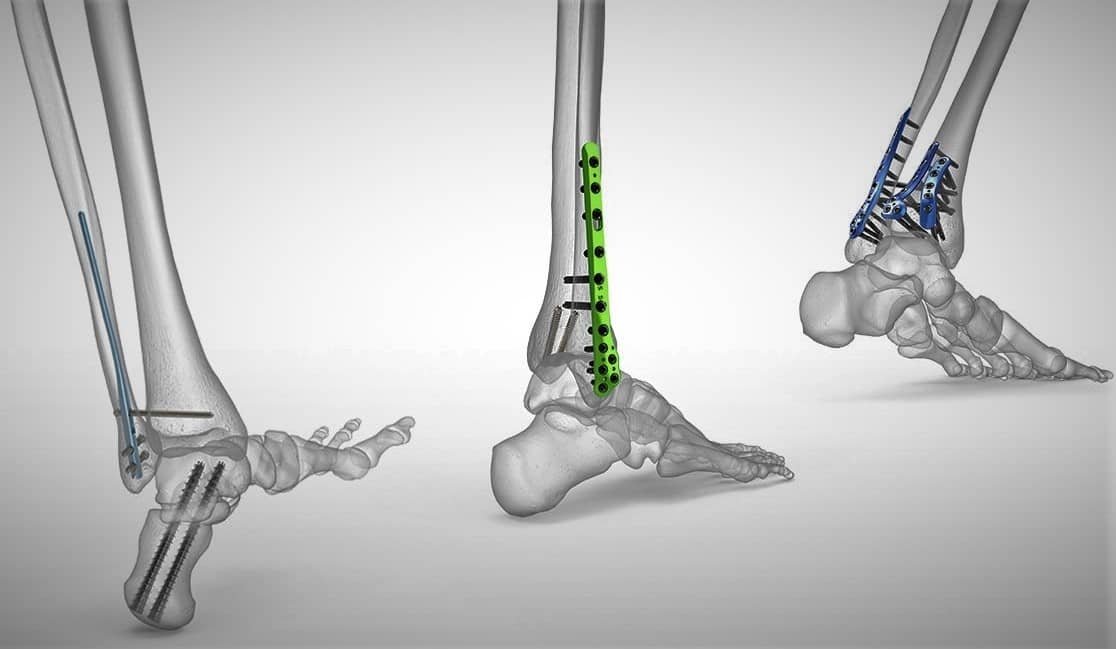

Medical Implants and Chemical Processing

Titanium bonds well with bone, so docs pick it for hip screws and tooth wires. Jingzhou coils bend into braces that last kids’ growth spurts. Chemical towers stir corrosives at 300°C; our wires line exchangers, stopping pinholes that dump $100,000 batches yearly.

Pick Jingzhou, an ISO9001 shop, for wire checked by infrared gauges on width, spectrometers on alloy mix, and pull testers on strength. Every 500kg coil passes or gets scrapped.

FAQ

Q: Is Jingzhou a trading company or a direct manufacturer?

A: We are a direct factory and manufacturer based in Tianjin, specializing in metal wire since 2009.

Q: What is the typical delivery timeframe for an order?

A: Generally, it is 7-15 days for in-stock items and 10-20 days for customized or out-of-stock orders.

Q: Can you provide customized specifications for titanium profile wires?

A: Yes, we offer fully customized services for wire diameters, opening sizes, and specific shapes based on your drawings.

Q: How does Jingzhou ensure the quality of its titanium wire?

A: We use infrared detectors for dimensions, spectrometer analysis for material grade, and tensile strength meters for mechanical testing.