Understanding Flow Control Requirements

Key Parameters in Industrial Flow Control

In industrial separation and filtration setups, picking the proper filter type starts with checking main flow control factors like flow rate, working pressure, and particle size. These elements play a big role in deciding the filter shape and the best slot or hole size to get the needed separation results. Also, how well screen materials match the handled substances—especially in tough spots with corrosion, high heat, or grinding wear—impacts both output and durability.

Common Applications in Separation and Filtration

Filters form key parts in many fields, from water treatment and mining to food handling and petrochemical work. Water treatment plants rely on filters to pull out solids and keep the output water clear. Mining sites use them for sorting large batches of materials and splitting them apart. In food lines, like those for juice filtering, filters matter a great deal for keeping product standards and cleanliness high.

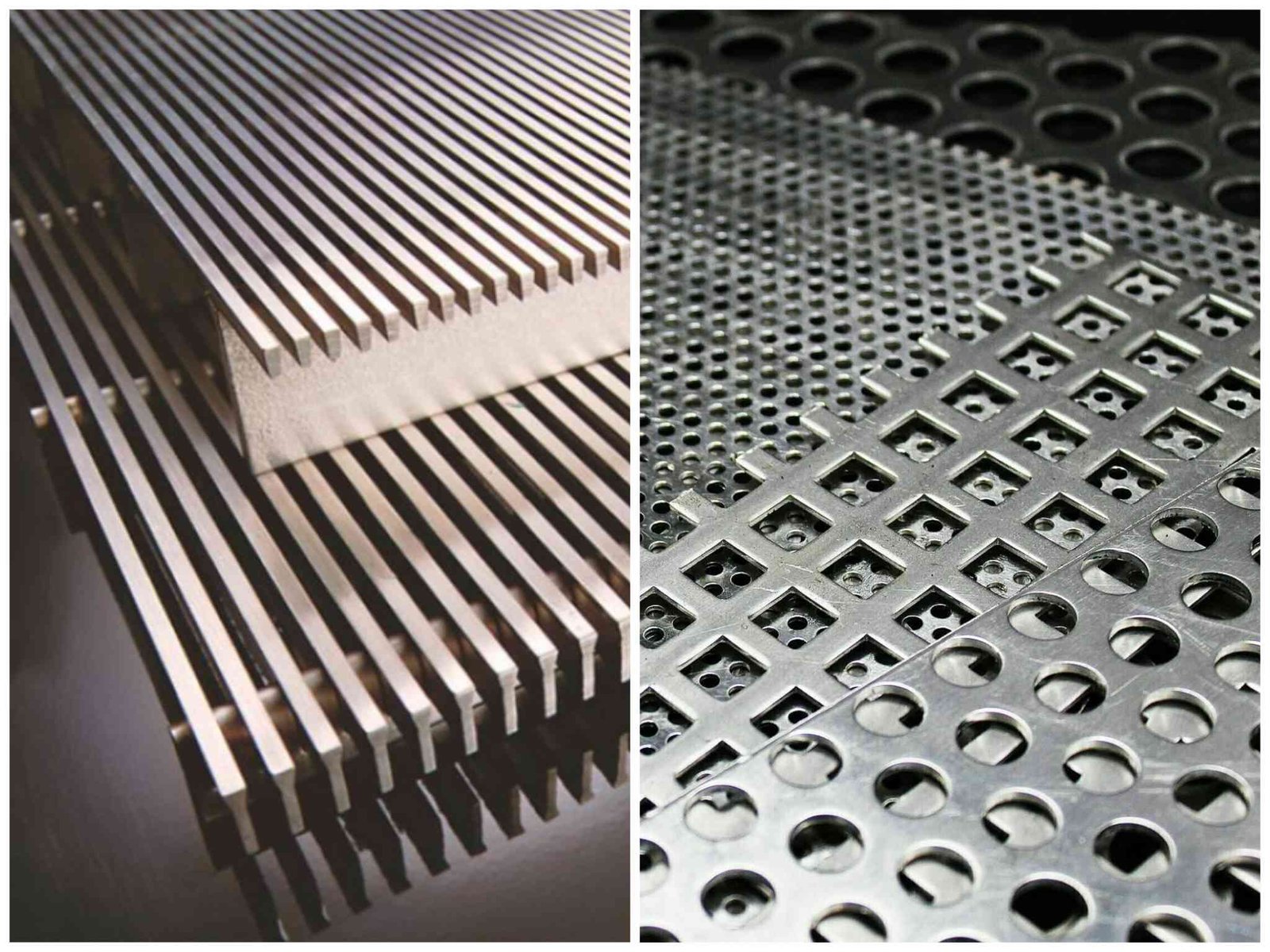

Comparing Wedge Wire and Perforated Sheet

Structural Differences

Wedge wire screens come from welding V-shaped profile wires to support rods, creating steady slots. This setup makes a sturdy wedge wire screen with slim slot gaps that widen inside, giving a built-in cleaning action. On the other hand, perforated sheets are basic flat metal panels with evenly punched holes in set patterns and sizes. Though easier to make, they usually lack the depth of wedge wire screens.

Performance Characteristics

Wedge wire screens deliver exact slot gaps from 0.05 mm to 3 mm with close controls, so they fit jobs that call for sharp filtration work. Their clog-resistant traits and slots that open wider inside support steady runs with little upkeep. Perforated sheets give more open space overall, but they miss the sharp cut of wedge wires. This often points them toward handling big material loads instead of detailed splitting.

Choosing the Right Solution Based on Needs

When to Choose Wedge Wire Screens

Go for wedge wire screens in cases where detailed filtration counts a lot, or where blockages could cause expensive stops in work. Think of wastewater plants, food lines, or systems for pulp filtering. They see broad use in areas like water treatment, oil and gas, mining, food handling, and pulp and paper. The self-cleaning setup cuts down on shutdowns for fixes.

When to Choose Perforated Sheets

For jobs with large solids or tight budgets—like drying grain or rough sorting in farming—perforated sheets might work better. They handle higher volumes but don’t hold fine bits well or manage exact flow needs.

Advantages of Jingzhou Wedge Wire Screens

Product Overview: Jingzhou Wedge Wire Screens

Jingzhou wedge wire screens delivers strong results from its top-quality stainless steel build. These wedge wire screens have slot sizes from 0.05 mm up to 3 mm with steady close controls. Stainless steel wedge wire screen (water well screen) includes warp rods and wires. The warp wire is a triangular wire (V-shaped wire). Built with clog-fighting shapes and high-build strength, they last longer even in hard industrial spots.

Application Scenarios for Wedge Wire Screens

Jingzhou’s wedge wire screens fit ongoing work in rough conditions like wastewater sites, pulp & paper operations, and food factories with strict clean rules. They can be used for many types of media filtration. These wedge wire screens keep their shape under heavy pressure and withstand rust risks.

Maintenance and Lifespan Considerations

Cleaning and Durability Comparison

Jingzhou’s wedge wire screens show better lasting power from their V-shaped slot setup, which cuts clog risks and supports good cleaning via backflushing. Non-clogging slots V-shaped wires allow the V-shaped slots to expand inward. This design leaves no space for sand particles to get stuck in the slots. Perforated sheets, by comparison, often build up junk in the punched holes and need hands-on cleaning more often.

Cost Over Time Analysis

Though wedge wire screens cost more at the start, their longer run and fewer fix-ups bring down total costs in the long haul. Perforated sheets look cheap upfront but wear down quicker and call for steady swaps, above all in grinding or rust-heavy spots.

Integration with Existing Systems

Customization Options from Jingzhou

Jingzhou offers broad, tailored fixes for wedge wire screens. This covers changes in slot/hole size, panel sizes, stainless steel types, and setup styles. We uphold the concept of serving customers well and provide optional customized services according to the product needs of different customers. OEM/ODM cooperation models ensure that Jingzhou products integrate seamlessly into your current system designs.

FAQ

Q: What is the main difference between wedge wire screens and perforated sheets?

A: Wedge wire screens use V-shaped wires for precise slot openings ideal for fine filtration; perforated sheets are flat metal plates with punched holes suited for coarse separation or structural use.

Q: Which product is better for wastewater treatment applications?

A: Jingzhou’s wedge wire screen is better suited due to its anti-clogging design, corrosion resistance, and accurate slot sizing, ideal for continuous flow filtration systems.

Q: Can I get custom-sized screens from Jingzhou?

A: Yes, Jingzhou provides fully customizable solutions, including dimensions, material grade, slot/hole size, and mounting configuration based on your system requirements.

Q: How do I choose between perforated sheet and wedge wire screen?

A: Choose perforated sheet if you need structural rigidity or coarse separation at a lower cost; choose wedge wire screen if you require precise flow control with reduced maintenance needs over time.