Why Stainless Steel Wedge Wire is Ideal for Marine Use

Corrosion Resistance in Harsh Saltwater Environments

In marine settings, saltwater and dampness speed up rusting. This makes picking the right materials key for filtration setups. Stainless steel wire works well in industrial filtering because of its strong resistance to corrosion, solid build, and ability to hold up in tough spots.

Jingzhou makes its wedge wire screens from top-quality stainless steel, like SS304 and SS316L. They fit well for setups that last for years, such as seawater intakes and ballast water systems.

Mechanical Strength and Structural Stability

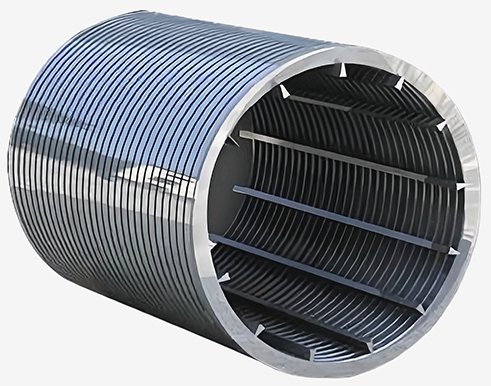

Marine jobs often face physical strain from waves, floating junk, and system pressure. Wedge wire mesh stands out for its lasting quality, solid strength, and resistance to corrosion. The V-shaped wires get welded to support rods. This creates a firm frame that can take heavy loads without bending or breaking.

Such a strong build keeps the structure sound in places like offshore platform filters and seawater reverse osmosis (SWRO) systems. The tough design also cuts down on how often you replace parts. That leads to smoother work and lower upkeep costs over time.

Key Features of Jingzhou Wedge Wire Screens

Precision Slot Openings for Accurate Filtration

One big plus for Jingzhou’s wedge wire screens is the way you can adjust slot sizes, from 0.02mm to 10mm. This exact control lets marine workers match filters to the exact bits they need to catch, like sand, plant scraps, or tiny sea creatures.

The setup cuts down on blockages and sudden drops in flow. With special making methods, slots can go as fine as 0.15mm. So, you pick the right size based on local sand grains.

V-Shaped Profile Design Enhances Efficiency

Jingzhou wedge wire screens use a V-wire setup where gaps get wider inside. These non-clogging slots from V-shaped wires let openings spread inward. No room for sand to jam up, so wedge wire screens stay clear. This shape pushes bits off the surface while filtering. It creates a self-cleaning action that builds longer life and cuts back on hand cleaning.

Application Scenarios in Marine and Aquatic Settings

Seawater Intake Screens for Desalination Plants

Jingzhou’s stainless steel wedge wire screens serve as intake guards in seaside desalination plants. They block sea animals and big trash from reaching delicate filters. The sturdy make lets them run for a long while under steady currents and rough wear, which keeps the whole system working right.

Aquaculture Filtration Systems

Fish farms need clear water to keep sea life healthy. Jingzhou’s wedge wire screens pull out food leftovers, seaweed bits, and floating dirt from pools and lakes. This leads to better air in the water and less chance of sickness, both vital for good output.

Offshore Platform Water Treatment Units

On offshore oil platforms and sea rigs, wedge wire screens are widely used in seawater intake systems, water injection units, produced water treatment, and cooling water filtration. They serve as primary and secondary filtration components in pumps and pretreatment stages, protecting downstream equipment from sand and debris. Designed to withstand high salinity, strong currents, and continuous operation, wedge wire screens help reduce biofouling, prevent clogging, and improve the reliability and efficiency of offshore water treatment systems.

Customization Options Offered by Jingzhou

Material Grades and Surface Treatments Available

Different sea areas call for different levels of rust protection, so Jingzhou supplies stainless steel wedge wires in grades like SS304, SS316L, duplex stainless steel, and titanium mixes if needed. We shape and build stainless steel profile wires to fit exact needs, such as wire thickness, gap sizes, and full measurements.

Extra finishes like electropolishing or passivation add more rust defense and smooth out surfaces to slow down slime growth.

Tailored Dimensions and Mounting Styles

Jingzhou offers wedge wire screens made to order, up to 6 meters long and with diameters from 25mm to 1000mm. End parts can be flanged, threaded, or welded to match the setup. These choices make fitting into fresh or old systems straightforward.

Maintenance Advantages of Stainless Steel Wedge Wire Screens

Easy Cleaning and Long-Term Cost Savings

The even surface on wedge wire keeps upkeep basic, usually just a rinse from behind or a high-pressure wash. Unlike old-style mesh that jams quickly and wears out fast, Jingzhou’s items last longer with less work needed.

Reusability Across Multiple Projects or Systems

The solid build means you can take wedge wire screens out, scrub them clean, and put them back without losing strength or shape. This fits them for fixed sea spots as well as moving gear like study boats or easy-to-move desalination kits.

FAQ

Q: What makes wedge wire screens suitable for desalination plant intakes?

A: Wedge wire screens from Jingzhou hold up well against saltwater rust thanks to the stainless steel build.

Q: How does the V-shaped profile improve filtration performance?

A: The V-wire shape makes slots wider inside, which pushes particles off the surface as it runs.

Q: Are Jingzhou wedge wire screens customizable for different flow rates or particle sizes?

A: Yes, we provide custom options like slot size from 0.02mm, length up to 6m, diameter 25mm–1000mm, material such as SS316L, and ends like flanges or threads.

Q: How do stainless steel wedge wires compare to plastic or mesh filters in marine use?

A: Stainless steel gives better power, rust fight, longer run time, and simple cleaning, all key to steady work in tough salt waters.