Importance of Stainless Steel Wire in Medical Devices

Why Stainless Steel Wire Matters in Healthcare

Hospitals run hot—134 °C steam, bleach, hydrogen peroxide, you name it. Anything that goes near a patient has to survive that punishment day after day and still stay clean and strong. That’s where 316L stainless wire shines. It doesn’t pit, it doesn’t rust, and it keeps its shape whether it’s holding a broken bone together for six months or getting bent a thousand times in an orthodontic archwire. Surgeons, dentists, and device makers all trust it because the body doesn’t react to it, and MRI machines don’t go crazy around it.

Jingzhou’s Stainless Steel Wire Advantages

Jingzhou has been drawing medical wire since 2009. Everything leaves the plant in 316L medical grade. We pull it dead round, hold the diameter within a couple of microns, and finish the surface so smooth that nothing sticks. You can get it from hair-thin 0.05 mm up to 2 mm stout pins—whatever the job calls for.

How Stainless Steel Wire Powers Critical Medical Tools

Applications in Surgical Instruments

Use in Scalpels, Forceps, and Scissors

Grab any tray in the OR, and half the tools started life as Jingzhou stainless steel wire. Scissors stay sharp after hundreds of autoclave runs, forceps don’t bend when the surgeon really clamps down, and needle holders grip tight without chewing up the suture. The wire laughs at fatigue, so the tip you pick up on case 50 feels the same as case one.

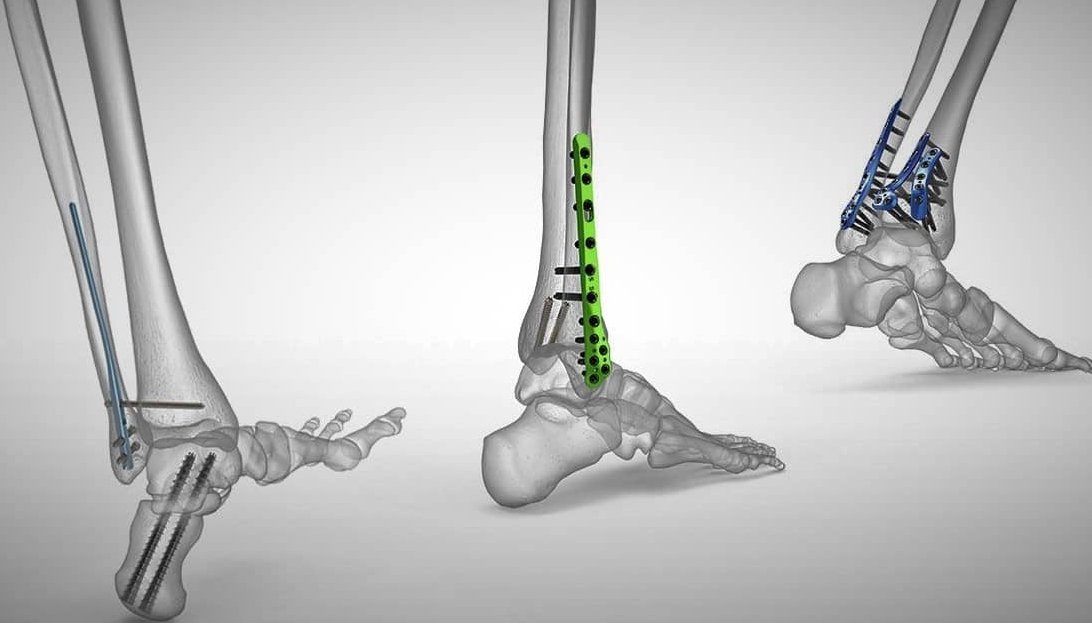

Role in Orthopedic Implants

Bone Plates, Screws, and Pins

Broken bones need something that won’t corrode while the fracture heals. Pins and screws made of Jingzhou stainless steel wire are non-magnetic (safe under MRI), strong enough to hold a femur together, and polished so tissue doesn’t get angry. Surgeons use them for everything from wrist fractures to spinal fusions. We ship them dead straight and burr-free, so the trauma guy isn’t fighting the hardware.

Integration into Dental Devices

Orthodontic Brackets and Archwires

Straight teeth start with a wire that can push hard for months and not take a set. Jingzhou stainless steel wire comes out slick and springy. Friction stays low, so teeth move faster, and patients complain less about sore cheeks. You’ll find it in traditional braces, lingual systems, and even some clear-aligner attachments.

Use in Diagnostic Tools

Biopsy Needles and Catheters

Getting a core sample or threading a central line means the wire core has to steer but not kink. Jingzhou stainless steel wire is flexible enough to follow a vessel around a corner yet stiff enough to push through scar tissue. The passivated skin keeps the wall happy while the doctor works under ultrasound.

Customization Options and Quality Control

Tailored Wire Dimensions and Finishes

Tell us what you need, and we’ll draw it. Want 0.18 mm for a new rotary file? Done. Need 1.5 mm pins cut to 180 mm lengths and packed fifty to a sterile pouch? No problem. Bright anneal, matte, electro-polish, passivation—pick your finish. We even wind spools the way your machine likes them, so you’re not fighting tangles on the line.

Manufacturing Standards at Jingzhou

The plant runs ISO 13485. Every coil gets a pull test, diameter check in ten spots, and surface inspection under the scope. Paperwork follows the wire from the melt to your dock, so when the FDA or EU auditor asks, you just hand over the folder. Nothing ships unless it passes.

Conclusion

From surgical tools to orthodontic systems and life-saving implants, stainless steel wire is the quiet backbone of modern medical devices. Jingzhou ensures every coil meets strict medical-grade standards, delivering precision, durability, and biocompatibility your products can rely on. With full customization and ISO-certified processes, we help device manufacturers build safer, stronger, and more efficient solutions.

If you’re developing or sourcing medical-grade stainless steel wire, contact Jingzhou today for expert guidance and tailored specifications.

FAQ

Q: What type of stainless steel is used in medical wires?

A: We use 316L medical grade—best corrosion resistance, fully biocompatible, and stays non-magnetic.

Q: Can stainless steel wire be used inside the human body?

A: Yes. Pins and screws made of Jingzhou stainless steel wire are made for long-term implants; the body accepts them without trouble.

Q: How do I choose the right wire diameter for my device?

A: Thin stuff (0.2–0.5 mm) for ortho and catheters, thicker (up to 2 mm) for bone pins. Tell us the job, and we’ll point you to the right one.

Q: Does Jingzhou offer custom stainless steel wire solutions?

A: Absolutely—custom diameter, length, finish, and packaging. We build exactly what your device needs.