Understanding Wedge Wire Basics

What Is Wedge Wire and Its Applications

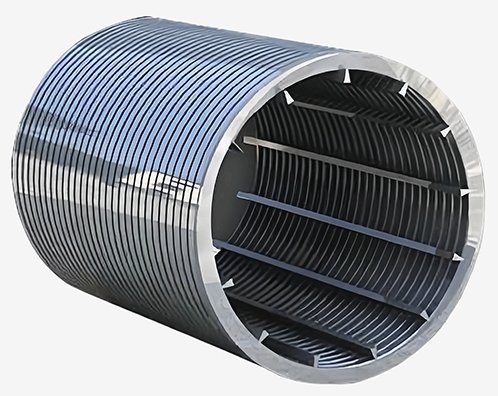

People also call it a profile bar or V-wire. It’s a special triangular wire that forms the working surface of industrial screens. The shape is narrow at the top and wider at the base, so liquid flows through easily while solids stay out. You’ll find these screens everywhere – water plants, mines, breweries, and oil refineries all depend on them. Curved screens made from wedge wire are especially common for dewatering coal or cleaning wastewater.

Jingzhou builds strong, hard-to-clog wedge wire screens. The Screen Cylinders handle big flow rates in factories, and the Wedge Wire Screen panels work just as well on building facades as they do inside separators.

Key Features of Stainless Steel Wire Used

Jingzhou sticks to 304 and 316L stainless steel. The 316L grade has extra molybdenum, so it laughs at saltwater and acid. Because the wire is shaped like a V, it stays strong even when the pressure climbs. The surface comes out smooth from the mill, which keeps food-grade and pharmaceutical jobs clean.

Essential Qualities Buyers Should Expect

Material Quality and Traceability

Good suppliers hand over mill certificates with every shipment. Jingzhou does exactly that. Those papers prove the steel really is 316L (or whatever grade you ordered) and came from a reputable mill. In water treatment or petrochemical jobs, that paperwork can save you from big trouble during an audit.

Precision in Slot Openings

The gap between wires has to be dead-on. Jingzhou keeps tolerances within ±0.02 mm across the whole screen. Miss by a hair and fine sand slips through, or the flow drops, and your pump works overtime. They’ll make you anything from a tight 0.05 mm slot for polishing filter to a wide 5 mm opening for gravel packs.

Welding Technology and Structural Integrity

Strong welds keep the screen from falling apart when pumps cycle or trucks drive over it. Jingzhou runs automated TIG welding machines so every joint looks the same and holds tight. In a vibrating mineral plant, cheap hand welds crack in weeks; these last for years.

Evaluating Supplier Capabilities

Customization Options Available

One size never fits all. Jingzhou will build whatever diameter, length, or slot you draw on the back of a napkin. Need titanium wire or copper? They do that too. The Wedge Wire Basket and Wedge Wire Screen lines are starting points – most jobs end up with custom end fittings or special shapes.

Production Capacity and Lead Time Assurance

Big projects can’t wait. Jingzhou keeps several production lines running, so even rush orders for twenty wedge wire cylinders ship in a couple of weeks instead of months.

Performance Metrics to Review Before Purchase

Flow Rate Efficiency and Debris Resistance

Open area matters. The Screen Cylinder design gives about 60% open area, which means more water moves through and less junk sticks. Municipal plants and mines love that combination.

Load-Bearing Strength Under Pressure Conditions

These wedge wire screens take real punishment. Jingzhou tests wedge wire panels to 300 PSI before they leave the factory, so they hold up in high-pressure injection wells or thick slurry lines.

After-Sales Support and Certifications Matter

Technical Support and Documentation Provided

You get proper CAD files, fitting drawings, and plain-English installation notes. The engineers will jump on a call if you’re not sure which way the flow arrow points.

Compliance With International Standards

Look for ISO 9001 on the door and ASTM numbers on the test reports. Jingzhou has both, so the screens pass inspection anywhere in the world.

Jingzhou keeps turning out tough, accurate wedge wire screens that show up on time and work for years – exactly what serious buyers need.

FAQ

Q: What certifications should I look for when buying wedge wire screens?

A: ISO 9001 for the factory and ASTM numbers for the steel. Jingzhou has both.

Q: Can I get customized wedge wire screens for non-standard equipment?

A: Yes. Tell us the size, slot, and fittings you need. The Screen Cylinders and the Wedge Wire Screen panels are routinely changed to fit.

Q: How can I be sure of the material quality used in my wedge wire screen?

A: Ask for the mill certificate. Jingzhou sends one with every order.

Q: Are your wedge wire screens suitable for high-pressure environments?

A: Definitely. They’re tested to 300 PSI and keep their shape.