Product Introduction

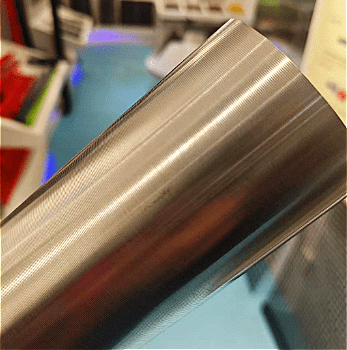

This product is a stainless steel wedge wire screen (Johnson screen).

It is primarily made of stainless steel (such as 304 or 316L for corrosion resistance) and features wedge-shaped wires wound to form uniform gaps. It also has internal support ribs to ensure structural strength.

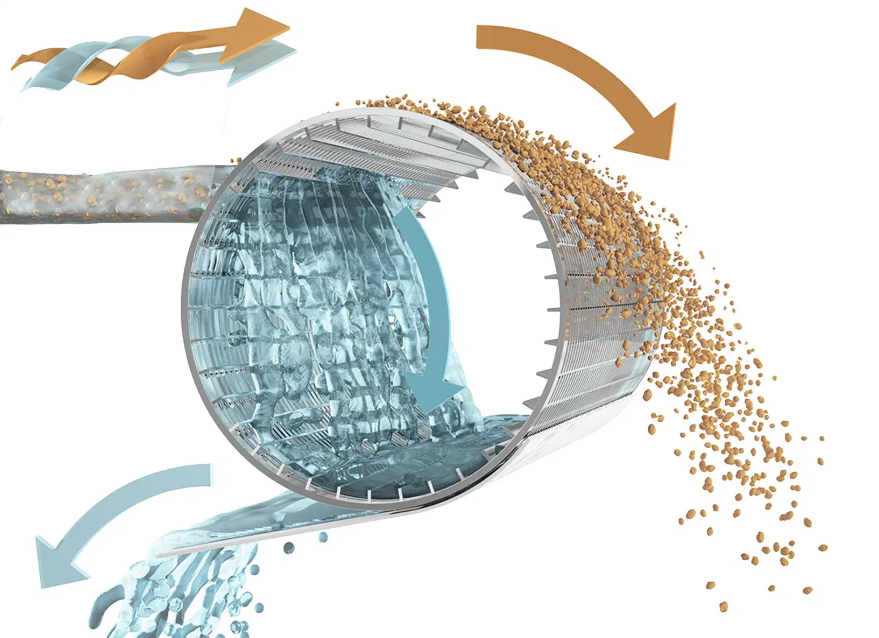

Designed for solid-liquid or gas-solid separation, it can trap impurity particles while allowing fluids (liquid or gas) to pass through. We widely use it in various industries, including oil and gas (for well sand control and drilling mud filtration), water treatment (for purifying drinking water and treating sewage), mining (for filtering mine drainage and separating slurry), chemicals (for filtering raw materials and recovering catalysts), and environmental protection (as a core filter element in self-cleaning filters and microfiltration equipment).

It has several advantages: we can control the filtration precision (by adjusting the gap width to meet different filtration requirements, ranging from microfiltration to coarse filtration), it has strong corrosion resistance (so it is suitable for harsh environments with corrosive media like acids, alkalis, high temperatures, and organic solvents), it offers excellent anti-clogging performance (the wedge structure prevents impurities from getting stuck and facilitates backwashing for easy maintenance), and it has high mechanical strength (so it can withstand high working pressures in complex conditions such as downhole and high-pressure filtration scenarios).

| Material | Stainless Steel 304, 302, 304L, 316, 316L, or as required |

| Filtration rate | 15-800μm |

| OD | 25.4-1200mm |

| Slot | 0.1mm-45mm |

| Wire | 2.0mm*30.mm,3.0mm*4.6mm,3.0mm*5.0mm |

| Rods | 3.8mm/22, 3.8mm/32, 3.8mm/48, 3.8mm/50 |

| Height | 6-40 mm |

| Performance | Corrosion-resisting, Wear-resisting, Tear-resisting. |

Production process:

We make the stainless steel strip gap screen—a screening and filtering device—from cold-rolled stainless steel strips. We then use automated machine tools to continuously wind and weld these strips onto support bars.

The minimum sieve gap can be 0.02mm: the maximum sieve gap is 20mm.

The minimum support distance can be 8-10mm: the maximum support distance is 75-80mm.

The cross-sectional shape and size of the sieve strip and support strip determine the overall strength and stiffness of the screen mesh. The back width of the sieve strip determines the aperture ratio of the screen gap. Different filtration and screening effects lead to different particle sizes of the separated material, so you should match them reasonably according to the space.

Stainless steel Filter mesh specifications:

| Sr. No. | WEDGE WIRE SCREEN Description |

| 1 | Size: Dia. 220 x 330 LG. Effective Size Of: 0.9 1.4 mm Media |

| 2 | Size: Dia. 220 x 330 LG. Effective Size Of: 0.8 0.9 mm Media |

| 3 | Size: Dia. 220 x 330 LG. Effective Size Of: 0.3 1.2 mm Media |

| 4 | Common Specification : MOC: SS 304 Flow Direction:OUT to IN Differential Pr. To: 6Kg/cm2 Withstand |

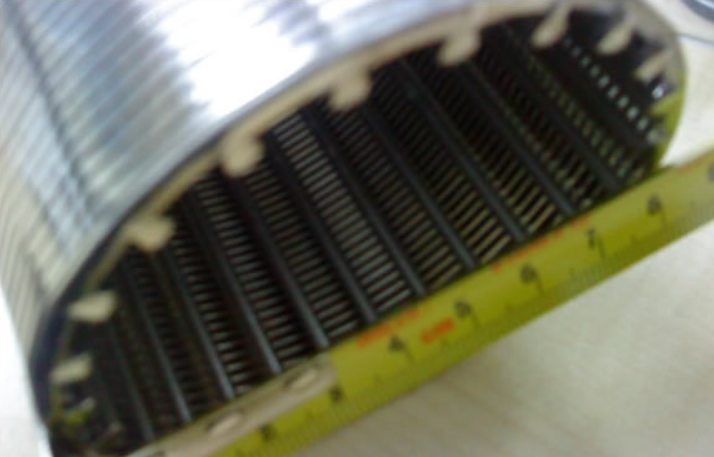

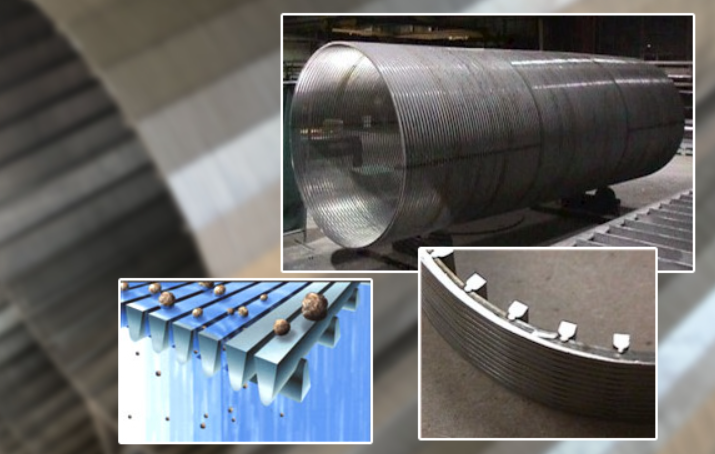

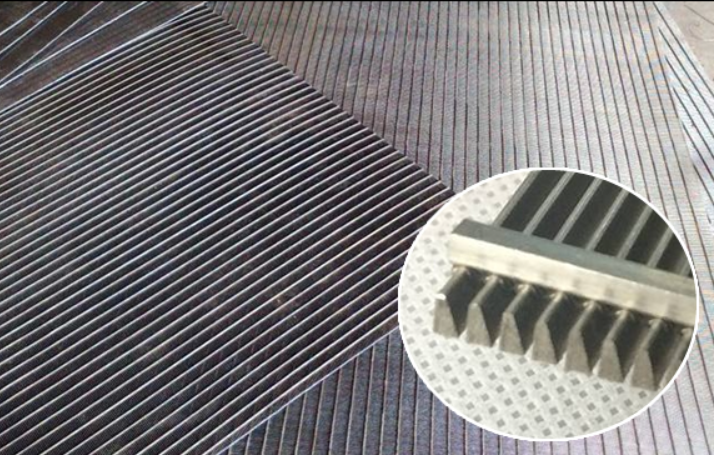

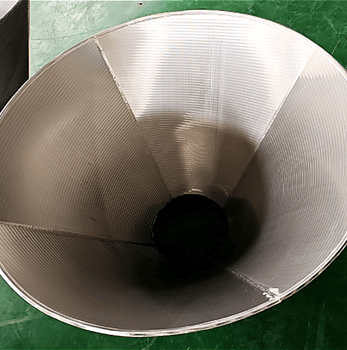

Detailed photos

Solid-liquid separation

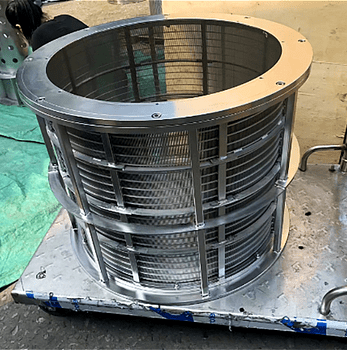

Stainless Steel Wedge Wire as Filter Insert/Screen

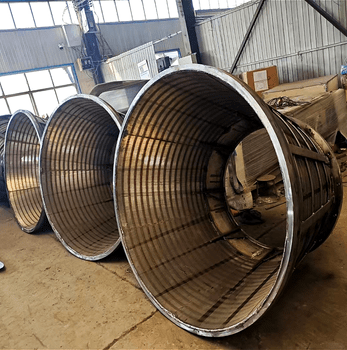

Stainless Steel Wedge Wire Screen in Cylinder Shape

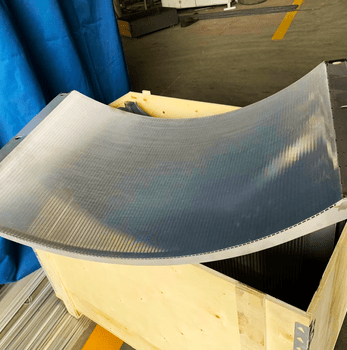

Stainless steel wedge wire screen filter in flat panels

Construction of SS Wedge Wire Screen:

We manufacture our stainless steel wedge wire well screens using unique computer-controlled machinery. In this equipment, we fusion-weld a continuous length of triangular-section stainless steel profile wire to support rods. We then wind this “V” shaped profile wire around the support rods along the full length of the screen, thereby creating a continuous slot opening.

| Available shapes | Unit/mm |

| 3×5 4×6 4×8 |

| 0.9×1.9 1.19×2.24 1.8×2.75 2.4×3.5 1.8×3.1 1.8×4.5 2.28×3.56 3×6 |

| 2.8×6.5 3×5 3×6.5 3.5×6.5 4×6.5 |

| 2.33×3.1 2×6.5 3×6 |

| 2.4×3.55 3.5×4 3×6.5 3×6 |

Stainless Steel Wedge Wire Screen is supplied with various surface profile and support profile considering design and maximum free flow area available with respect minimum withstand differential pressure. In cylinder and sheets for rotary drums and sieves.

Funnel sieve

Screen tube

Drum Screen