Product Overview

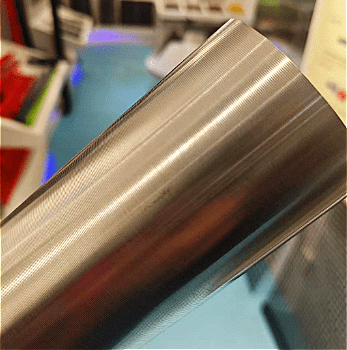

Manufacturers weave or weld high-quality stainless steel wire into stainless steel screens, which boast excellent corrosion resistance, high temperature resistance and mechanical strength. Its surface is smooth, durable and capable of long-term use in harsh environments. The screen has uniform pore size and high filtration precision, and is suitable for precise screening and filtration of liquids, gases and solid particles. Due to the diversity of its materials, such as 304, 316, 904L stainless steel, etc., screens can be widely used in chemical, food processing, pharmaceutical, petroleum, mining and other industries. According to different needs.

Stainless steel screens not only provide excellent performance, but also have good processability. The size, shape and weaving density can be customized according to customer needs, and are widely used in various industrial and civil scenarios.

| Material | Stainless Steel 304, 302, 304L, 316, 316L, or as required |

| Filtration rate | 15-800μm |

| OD | 25.4-1200mm |

| Slot | 0.1mm-45mm |

| Wire | 2.0mm*30.mm,3.0mm*4.6mm,3.0mm*5.0mm |

| Rods | 3.8mm/22, 3.8mm/32, 3.8mm/48, 3.8mm/50 |

| Height | 6-40 mm |

| Performance | Corrosion-resisting, Wear-resisting, Tear-resisting. |

Production process:

Stainless steel strip gap screen is a screening and filtering device made of cold-rolled stainless steel strips, which are continuously wound and welded by automated machine tools through support bars.

The minimum sieve gap can be 0.02mm: the maximum sieve gap is 20mm

The minimum support distance can be 8-10mm: the maximum support distance is 75-80mm

The cross-sectional shape and size of the sieve strip and support strip determine the overall strength and stiffness of the screen mesh. The back width of the sieve strip determines the aperture ratio of the screen gap. Different filtration and screening effects lead to different particle sizes of the separated material, so you should match them reasonably according to the space.

Stainless steel Filter mesh specifications:

| Sr. No. | WEDGE WIRE SCREEN Description |

| 1 | Size: Dia. 220 x 330 LG. Effective Size Of: 0.9 1.4 mm Media |

| 2 | Size: Dia. 220 x 330 LG. Effective Size Of: 0.8 0.9 mm Media |

| 3 | Size: Dia. 220 x 330 LG. Effective Size Of: 0.3 1.2 mm Media |

| 4 | Common Specification : MOC: SS 304 Flow Direction:OUT to IN Differential Pr. To: 6Kg/cm2 Withstand |

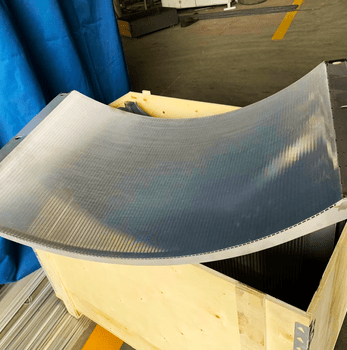

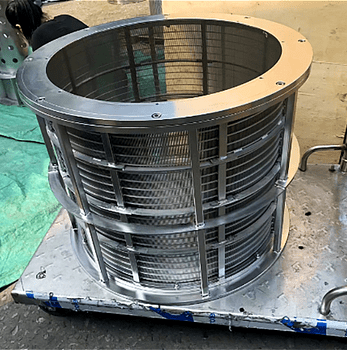

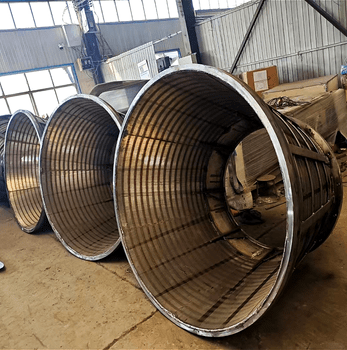

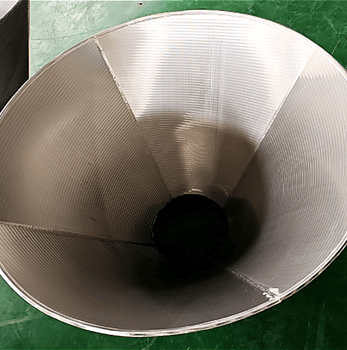

Detailed photos

Construction of SS Wedge Wire Screen:

We manufacture our stainless steel wedge wire well screens using unique computer-controlled machinery. In this process, we fusion-weld a continuous length of triangular-section stainless profile wire onto support rods. Then, we wind this ‘V’ shaped profile wire around the support rods along the full length of the screen, thereby creating a continuous slot opening.

Screen gap 1mm

Support distance 50mm

| Available shapes | Unit/mm |

| 3×5 4×6 4×8 |

| 0.9×1.9 1.19×2.24 1.8×2.75 2.4×3.5 1.8×3.1 1.8×4.5 2.28×3.56 3×6 |

| 2.8×6.5 3×5 3×6.5 3.5×6.5 4×6.5 |

| 2.33×3.1 2×6.5 3×6 |

| 2.4×3.55 3.5×4 3×6.5 3×6 |

Stainless Steel Wedge Wire Screen is supplied with various surface profile and support profile considering design and maximum free flow area available with respect minimum withstand differential pressure. In cylinder and sheets for rotary drums and sieves.

Funnel sieve

Screen tube

Drum Screen

Questions you may be interested in

What special pricing or shipping options are available for wedge wire screens?

Looking for a tailored quote or want to explore special pricing on our wedge wire screens? We offer competitive, volume-based discounts for bulk orders and custom manufacturing runs. Simply let us know your specifications and quantity requirements, and our team will provide you with a personalized quotation to fit your project’s needs.

As for shipping, we work with established carriers like DHL, FedEx, and UPS to ensure prompt global delivery. We calculate shipping charges at checkout based on your order size and location, and we always offer expedited options if you’re working on a tight timeline.

Let us know your delivery address and timeline, and we’ll walk you through all available shipping methods and costs before you place your order.