Introduction

Stainless steel wedge wire technology represents a critical advancement in industrial filtration and separation systems. Characterized by its precision-engineered V-profile wires welded onto robust support rods, this versatile material delivers unmatched durability, corrosion resistance, and customizable performance across demanding sectors—from wastewater management to mining and food processing.

What is the wedge wire

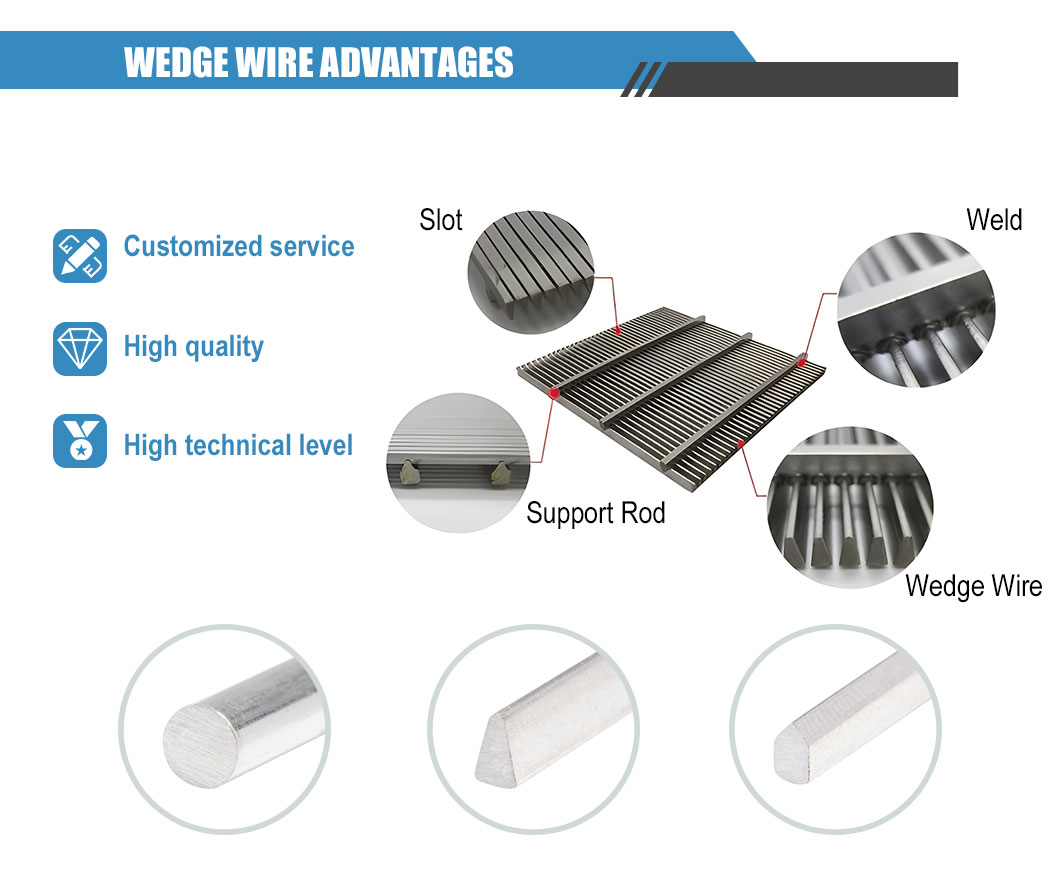

Wedge wire, or as it’s sometimes referred to, profile bar, is primarily used in the manufacture of screens. It is categorized as a type of screen wire because it belongs to a family of shapes that are used to manufacture screens, which are used in a wide variety of applications. The product has a triangular shape that varies in height, width and radius on both the nose and corners.

Design and Manufacturing Principles

Wedge wire screens are fabricated through automated resistance welding, where trapezoidal wires (typically 304, 316L, or duplex stainless steel) are fused perpendicularly to support rods. This process creates uniform slot openings ranging from 20µm to 25mm, with key structural advantages:

Tapered Slot Geometry: Prevents particle clogging through inward-to-outward widening.

Continuous Slot Design: Maximizes open filtration area (up to 40%) versus perforated plates.

Alloy Versatility: Adaptable to corrosive (316L), high-temperature (310S), or abrasive (Duplex 2205) environments.

Technical Advantages Over Conventional Screens

| Parameter | Wedge Wire | Perforated Plate | Woven Mesh |

| Clog Resistance | Excellent (Tapered slots) | Moderate | Poor |

| Structural Rigidity | Self-supporting | Limited span strength | Prone to deformation |

| Custom Slot Accuracy | ±0.02mm tolerance | ±0.5mm tolerance | N/A |

| Service Life | 10-15 years (avg.) | 3-7 years | 1-4 years |

Data based on ASTM F1783 industrial screening benchmarks

Industrial Applications

1. Water & Wastewater Treatment

In water and especially wastewater treatment, wedge wire screen tubes general offer strong corrosion resistance due to harsh and chemically aggressive environments. They are typically made from stainless steel such as 304 or 316L, with precise slot openings and high mechanical strength to ensure reliable filtration, easy backwashing, and long service life. These screens are widely used in intake filtration, media retention, and sludge dewatering.

Sieve Bend Screens: Remove >95% of solids at headworks (e.g., 0.25mm slots for grit capture).

Screew Press Liners: Enable sludge dewatering with continuous 50-100µm slots.

2. Mining & Mineral Processing

In mining and mineral processing, wedge wire screens must resist heavy wear, aggressive media, and remain non-magnetic. They are widely used in scalping screens and centrifuge baskets, typically made from stainless or duplex steel for strength, durability, and long service life. Based on field performance in the Russian market, our factory has specially developed grade 809C — a material with enhanced wear and corrosion resistance tailored for harsh mining environments.

Scalping Screens: Classify coarse ores using 5-25mm openings.

Centrifuge Baskets: Recover precious metals with wear-resistant duplex steel profiles.

3. Food & Pharmaceutical Production

FDA-Compliant Filters: 316L screens for juice clarification (100-500µm slots).

Fluid Bed Dryers: Uniform airflow distribution in powder processing.

Custom Engineering Capabilities

Leading manufacturers offer tailored solutions including:

Slot Optimization: Laser-calibrated apertures for target particle retention.

Non-Standard Geometries: Cylindrical, curved, or pyramidal screen profiles.

Specialized Alloys: Hastelloy® for extreme acidity, Super Duplex for seawater resistance.

Automated Weld Integrity: 100% eddy current testing per EN 10246-3 standards.

Selection Guidelines for Engineers

When specifying wedge wire systems, consider:

- Flow Dynamics: Slot velocity ≤ 0.3 m/sec to prevent blinding.

- Particle Load: Bridge-resistant designs for >15% solids concentration.

- Chemical Compatibility: Alloy selection via ISO 8044 corrosion mapping.

- Thermal Expansion: Differential rates between wires/supports (e.g., 304SS: 17.2 µm/m·K).

Conclusion

Stainless steel wedge wire technology delivers precision separation solutions where conventional screens fail. Its engineered balance of maximum open area, zero-clog operation, and decade-scale service life makes it indispensable for CAPEX-intensive processes. As industries face stricter filtration mandates and rising material costs, wedge wire’s total lifecycle value continues to drive adoption.

→ Explore Product Catalog: [Link to Product Datasheets]

→ Consult Our Engineers: [Link to Contact Form]