Role of Filtration in the Paper Industry

Importance of Efficient Filtration

In any paper mill, keeping the pulp clean is a big deal. Good filtration pulls out dirt like sand, bark chips, shavings, and chunks of uncooked fiber before they reach the paper machine. When those things slip through, you end up with specks in the sheet, weak spots, or rough surfaces that customers send right back.

Strong screens also save money on raw material. A typical recycled-newsprint mill can catch 8–15 tons of good fiber a day. That fiber heads straight back to the machine chest instead of the sewer. Thickeners fitted with the right screens can push stock from 0.8–1 % consistency up to 5–6 % before the headbox, so the machine runs faster, and the dryers use less steam.

Common Filtration Challenges

Paper stock is rough on equipment. Virgin Kraft pulp coming from the digester still has bark specks and sand that chew up regular screens in weeks. Acidic cooking liquids and high temperatures make ordinary mild-steel screens rust away fast.

Old-style perforated plates and wire-mesh baskets have another problem: the holes or gaps change size over time. A hole that starts at 0.25 mm can wear to 0.40 mm in a couple of months. When gaps open up, big junk slips through, and tears or breaks wires on the paper machine. Mills then have to slow down or shut down again.

Advantages of Wedge Wire Screen Technology

Structure and Functionality of Wedge Wire Screens

Wedge wire screens look different from the usual round-hole plates. Workers weld V-shaped wires side by side onto support rods. The narrow part of the V faces the incoming stock, so solids ride along the surface instead of sticking in the opening. The slots stay open, and pulp flows through smoothly.

Because every wire is welded at each crossing, the whole panel stays rigid even when stock hits it hard or the machine vibrates. Mills that run 1,000–1,500 kPa pressure on their screens rarely see these panels bend or break.

Benefits Over Conventional Screens

The V-shape gives the screen a natural back-flush action. Most fibers simply slide off instead of lodging in the slot. Slot sizes stay exact. Factories make these screens with gaps as fine as 0.05 mm and hold that size within a few microns across the whole panel. That means the same amount of good fiber passes every minute, day after day.

Stainless steel grades like SS304 and SS316L laugh at the acid conditions inside a bleach plant or recycled-fiber system. Where a mild-steel basket might last six months, a wedge wire basket often runs three to five years.

Jingzhou Wedge Wire Products for Paper Applications

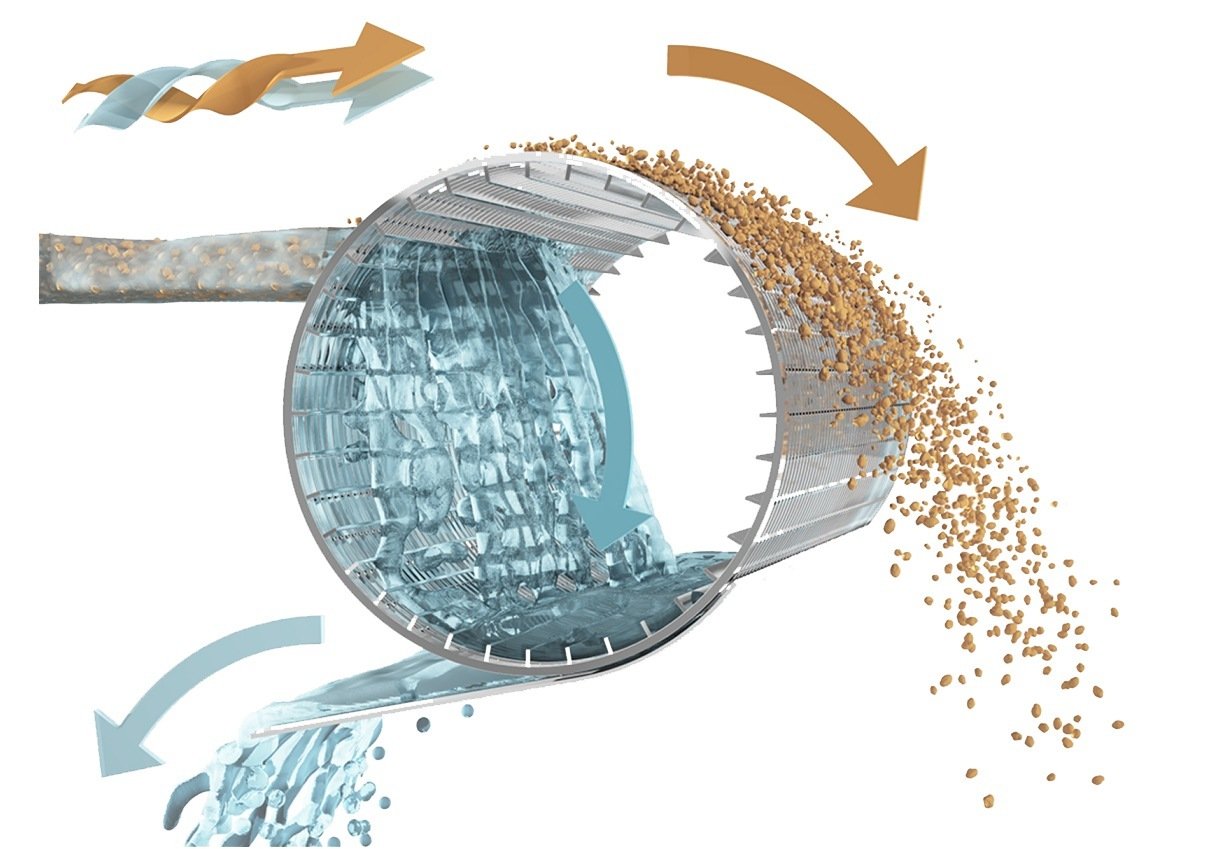

Jingzhou Drum Wire Screen

The Drum Wire Screen keeps turning slowly while stock flows across the outside. Rotation spreads the load evenly and keeps debris from building up in one spot. Mills handling OCC or mixed waste loves these drums because they handle heavy dirt loads without constant cleaning.

Jingzhou Wedge Wire Basket

The Wedge Wire Basket sits inside medium-consistency or high-consistency pressure screens. Fine slots down to 0.10 mm catch stickies and sand while still letting good fiber through at high speed. Many tissue and fine-paper mills use this basket in their final screening stage to protect the headbox and keep basis-weight variation low.

Key Considerations When Choosing a Wedge Wire Screen

Material Grade and Corrosion Resistance

Pick SS316L when the stock stays below pH 4 or when chlorine dioxide is part of the bleaching sequence. Use SS304 when conditions are milder. Both grades handle the heat coming off a Kraft brown-stock washer without trouble.

Slot Size Selection Based on Application Needs

For headbox screening on printing grades, most mills run 0.10–0.15 mm slots. Thickeners and white-water screens usually open up to 0.35–0.50 mm, so flow stays high, and pumps do not cavitate.

For paper mills that want screens that simply work year after year, Jingzhou stainless steel wedge wire products give tough service, exact separation, and the flexibility to fit almost any machine on the floor.

FAQ

Q: What is a wedge wire screen used for in the paper industry?

A: It filters pulp, catches dirt, thickens stock, and recovers good fiber so the mill runs cleaner and cheaper.

Q: Why choose stainless steel wedge wire over perforated plates?

A: It lasts years instead of months, almost never plugs, keeps exact slot size, and stands up to acid and heat.

Q: Can I customize the wedge wire screen size or shape?

A: Yes. Jingzhou builds to your drawings—any length, width, diameter, slot size, and mounting style.

Q: How often should I clean my wedge wire screen?

A: Light back-flush every shift usually does the job. Heavy recycled grades may need a proper wash-down once a week.