Features

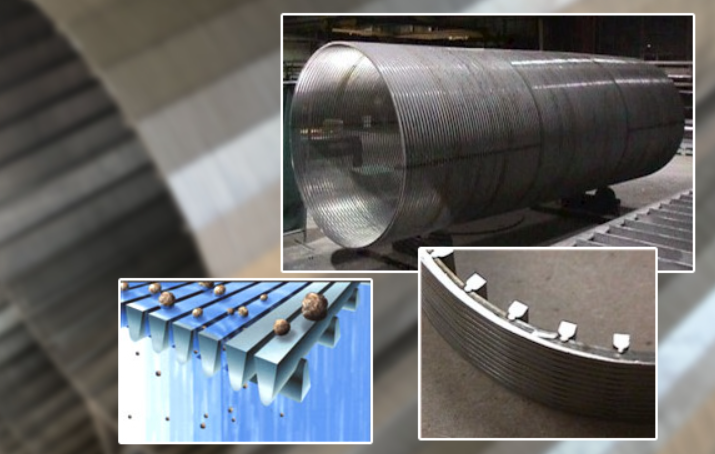

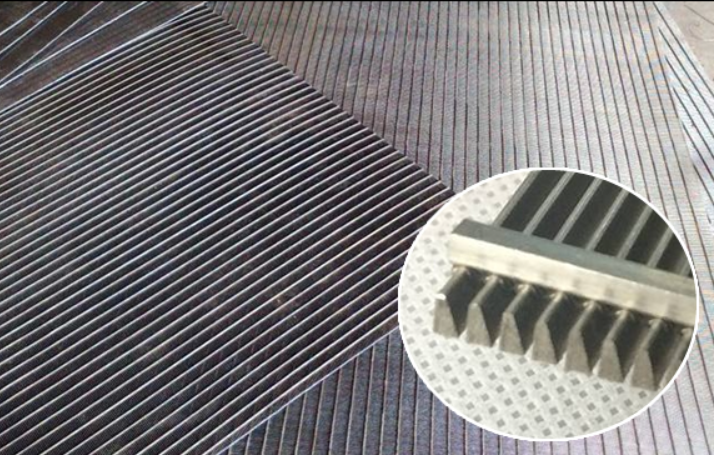

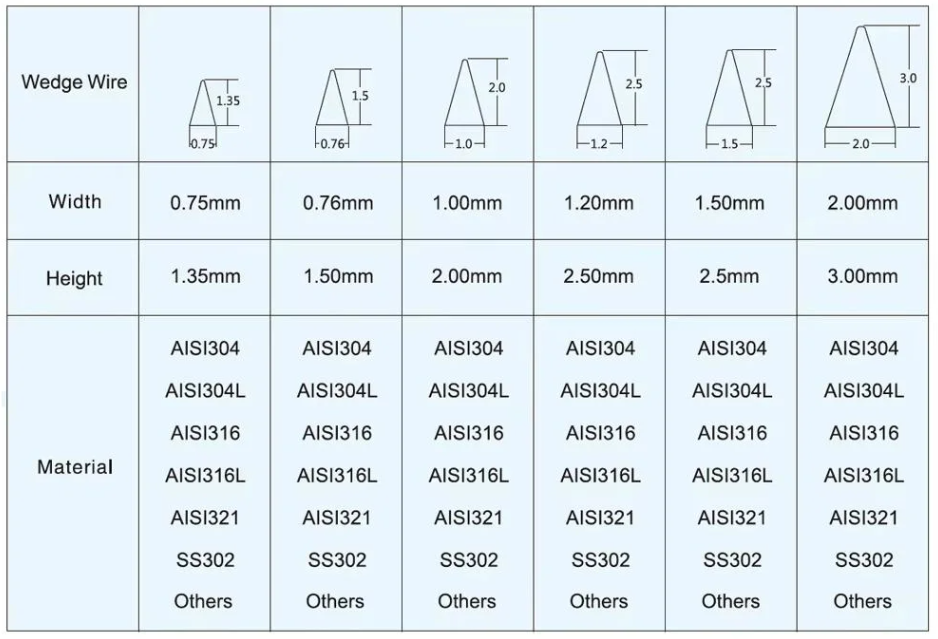

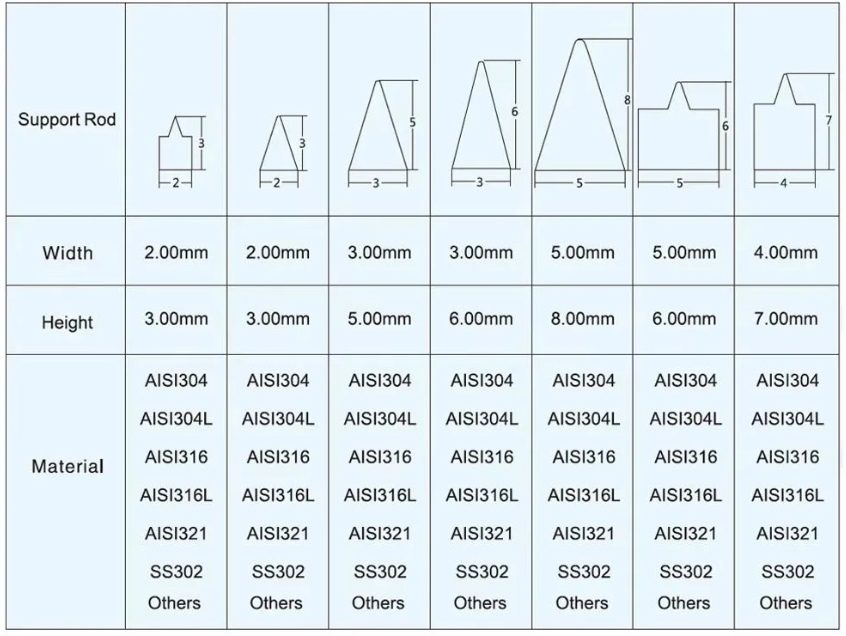

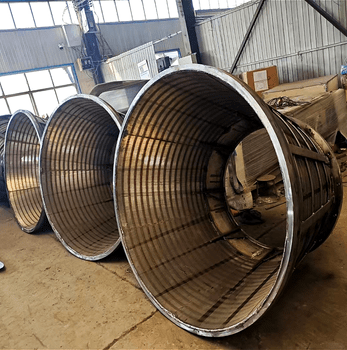

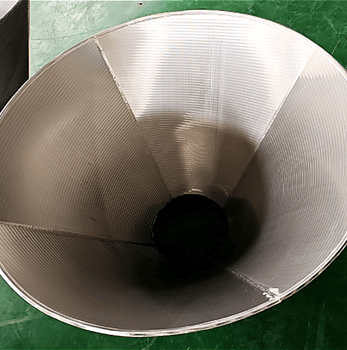

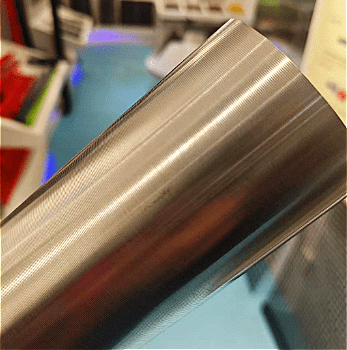

Stainless steel wedge wire screen baskets are constructed with trapezoidal-section wires (wedge wires) welded to support rods, forming a continuous, precise slot structure. Key features include:

- High-precision slot openings (ranging from a few microns to several millimeters) with uniform spacing;

- Robust stainless steel base (typically 304, 316L, or duplex stainless steel) for structural stability;

- Smooth surface (optional polished/ passivated finish) and rigid frame design;

- Corrosion-resistant and wear-resistant base material, adaptable to modified surface treatments.

Advantages

- Superior Filtration Performance: The wedge-shaped slot design prevents clogging by allowing particles to slide off easily, ensuring consistent flow rates and long-term operational efficiency.

- Durability: Stainless steel’s inherent corrosion resistance (against chemicals, saltwater, and moisture) combined with the welded structure delivers excellent mechanical strength, resisting impact and deformation even in harsh conditions.

- Hygiene & Safety: Food-grade and pharmaceutical-grade stainless steel options meet strict sanitary standards, with non-toxic, easy-to-clean surfaces that avoid contamination.

- Customizability: Available in various sizes, slot widths, and configurations (cylindrical, conical, rectangular) to fit specific equipment and application needs.

Applications

Widely used across industries for screening, filtering, and separation:

New Energy: Sieving lithium battery slurries and photovoltaic silicon materials. particularly rigid and rugged, they can be disassembled without risk of damage to the filter surface.

Food & Beverage: Sieving flour, starch, and sugar; filtering beer, dairy products, and fruit juices.

Water Treatment: Municipal/industrial wastewater filtration, seawater desalination (pretreatment), and drinking water purification.

Chemical & Pharmaceutical: Filtering acids, alkalis, and chemical slurries; processing pharmaceutical raw materials.

Mining & Metallurgy: Ore classification, tailings dewatering, and smelting slag treatment.

| Material | Stainless Steel 304, 302, 304L, 316, 316L, or as required |

| Filtration rate | 15-800μm |

| OD | 25.4-1200mm |

| Slot | 0.1mm-45mm |

| Wire | 2.0mm*30.mm,3.0mm*4.6mm,3.0mm*5.0mm |

| Rods | 3.8mm/22, 3.8mm/32, 3.8mm/48, 3.8mm/50 |

| Height | 6-40 mm |

| Performance | Corrosion-resisting, Wear-resisting, Tear-resisting. |

Stainless steel Filter mesh specifications:

| Sr. No. | WEDGE WIRE SCREEN Description |

| 1 | Size: Dia. 220 x 330 LG. Effective Size Of: 0.9 1.4 mm Media |

| 2 | Size: Dia. 220 x 330 LG. Effective Size Of: 0.8 0.9 mm Media |

| 3 | Size: Dia. 220 x 330 LG. Effective Size Of: 0.3 1.2 mm Media |

| 4 | Common Specification : MOC: SS 304 Flow Direction:OUT to IN Differential Pr. To: 6Kg/cm2 Withstand |

Related products

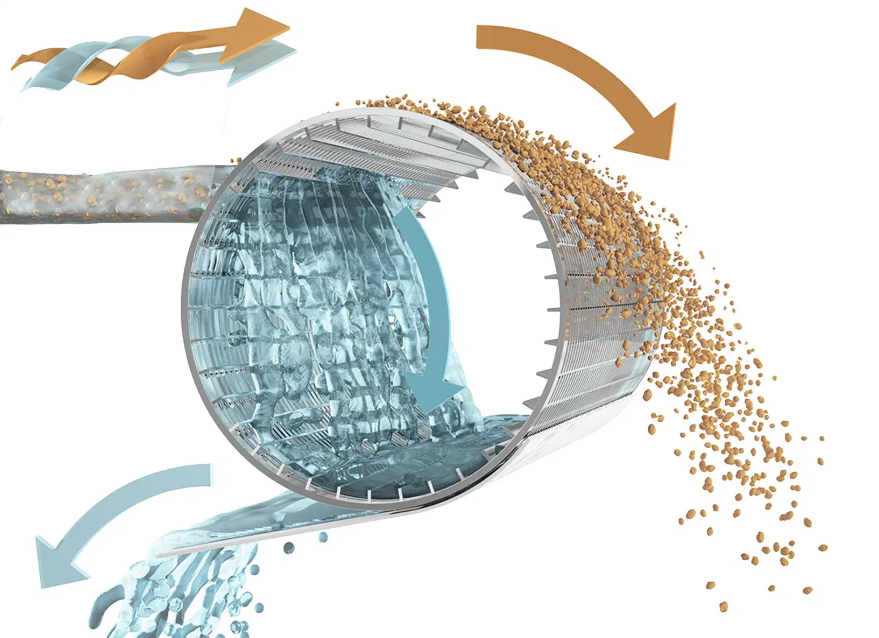

Solid-liquid separation

Stainless Steel Wedge Wire as Filter Insert/Screen

Construction of SS Wedge Wire Screen:

We use unique computer-controlled machinery to manufacture our stainless steel wedge wire well screens: we fusion-weld a continuous length of triangular-section stainless profile wire onto support rods. We then wind this “V” shaped profile wire around the support rods along the full length of the screen, which creates a continuous slot opening.

Screen gap 1mm

Support distance 50mm

| Available shapes | Unit/mm |

| 3×5 4×6 4×8 |

| 0.9×1.9 1.19×2.24 1.8×2.75 2.4×3.5 1.8×3.1 1.8×4.5 2.28×3.56 3×6 |

| 2.8×6.5 3×5 3×6.5 3.5×6.5 4×6.5 |

| 2.33×3.1 2×6.5 3×6 |

| 2.4×3.55 3.5×4 3×6.5 3×6 |

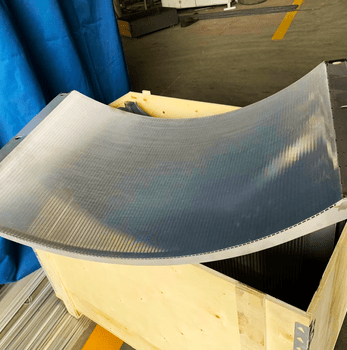

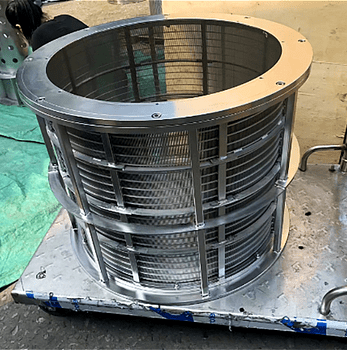

We supply Stainless Steel Wedge Wire Screens with various surface profiles and support profiles. We make these considerations based on the design, maximum available free flow area, and minimum withstand differential pressure. In cylinder and sheets for rotary drums and sieves.

Curved screen

Screen cylinder

Screen basket

Funnel sieve

Screen tube

Drum Screen