Understanding Wedge Wire Screens

What Are Wedge Wire Screens

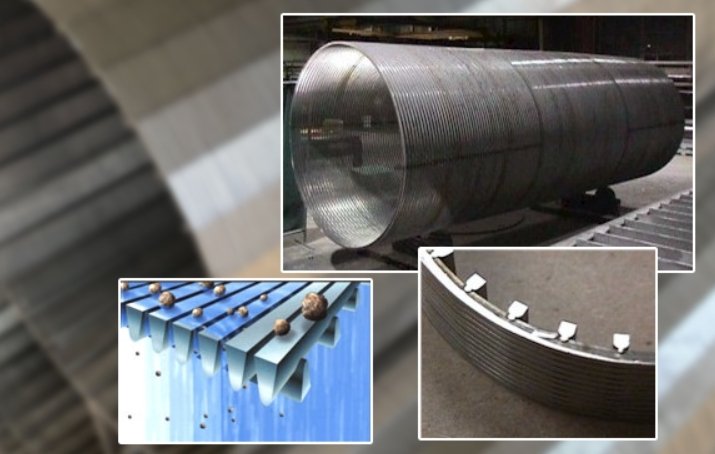

Wedge wire screens are made from stainless steel wires formed into a V shape. These wires get welded to support rods, forming long, narrow gaps that separate solids from liquids or gases accurately. The design reduces blockages and maintains steady flow. Workers in various fields appreciate them for their strength, solid construction, and resistance to corrosion. Common spots for these screens include water plants, oil rigs, mining operations, food production areas, and paper factories.

Key Features of Jingzhou Wedge Wire Screens

Jingzhou builds wedge wire screens using high-quality stainless steel, primarily grades 304 and 316L. Such materials resist rust effectively and remain firm under stress. Stainless steel wedge-welded wire screen (water well screen) includes warp rods and wires. The warp wire takes a triangular form (V-shaped wire). Wedge wire screen (water well screen) provides a solid frame, good open area, and exact slot width.

Slot sizes range from 0.02mm to 10mm, adjusted to suit different tasks. Screens appear in forms such as flat panels, cylinders, baskets, or curved pieces, allowing easy placement in various equipment.

Benefits of Using Jingzhou Wedge Wire Screens

High Filtration Efficiency

Jingzhou wedge wire screens prevent particles from lodging in the gaps. This keeps the screens open and free from clogs. Slots widen inward, so debris like sand slides past or rinses off without trouble. Steady flow continues even under heavy use, much like in municipal wastewater plants that process large amounts daily.

Precise gap spacing holds back specific particle sizes while permitting smooth liquid passage. These features make the screens reliable for demanding work that requires consistent performance and high volume handling.

Durability and Low Maintenance

Jingzhou screens use materials that stand against rust and chemical attack. They perform well in difficult conditions, including salty or acidic settings. The strong build resists bending under pressure, leading to less need for replacements over time.

Flat, clean surfaces allow quick washing, which shortens downtime in active facilities.

Applications in Wastewater Treatment

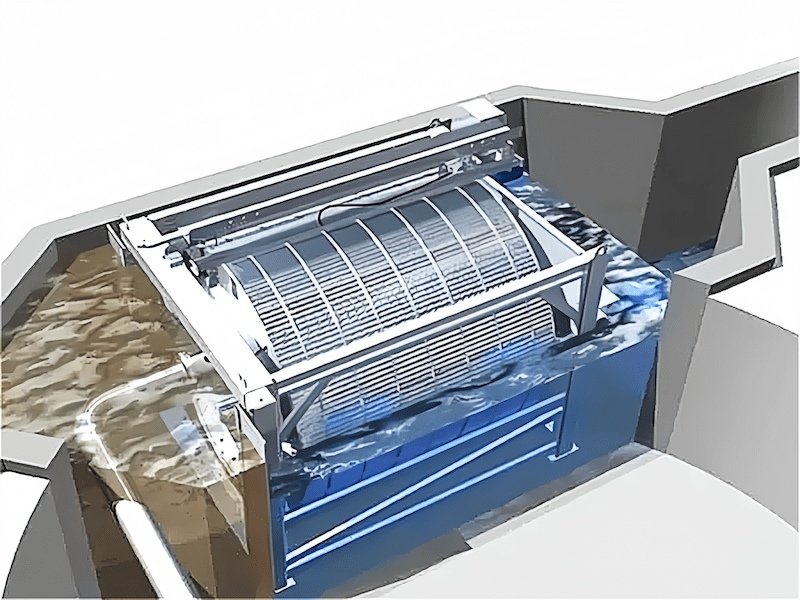

Primary Filtration Units

Wedge wire screens serve in numerous municipal and industrial wastewater plants. They remove larger debris at the start, clearing the way for later treatment phases.

Wide openings and tough structure let them manage rapid inflows full of solids, holding up through regular daily operation.

Sludge Dewatering Systems

In sludge handling, wedge wire screens separate solids from dense mixtures. This happens often in paper production, textile coloring, and food processing, where sludge gets thick and challenging.

The gap layout deals with sticky materials effectively. Screens avoid clogs and maintain function after extended periods.

Customization Options from Jingzhou

Tailored Slot Sizes and Dimensions

Jingzhou produces wedge wire screens matched to particular client requirements. Workers adjust gap widths for either very fine or coarser separation, based on the job.

Choices cover flat sheets, curved panels for sieve setups, screen cylinder for centrifuges, or tapered forms for certain installations.

Integration with Existing Equipment

Jingzhou wedge wire screens slide into current setups with little adjustment. Staff craft them to match typical filter bodies or unique designs. Compatibility includes rotary drums, sieve bends, pressure filters, and related machines.

Such fitting keeps work flowing during changes and frequently improves system output.

Why Choose Jingzhou Products

Advanced Manufacturing Technology

Factory equipment like CNC units manages welding and gap formation with reliable precision. Firm joints and uniform spacing appear in each batch.

Testing involves spectrometers for material checks and pull tests on samples to verify strength.

Expert Stainless Steel Solutions

Selecting Jingzhou connects you with a firm holding over ten years in stainless steel wire production. Staff apply current techniques and stress quality along with tailored solutions. Every wedge wire screen addresses the precise needs of your separation work.

FAQ

Q: What are the advantages of using wedge wire screens over traditional mesh or perforated plates?

A: Wedge wire screens give sharper particle control through even openings and stay clearer longer than perforated plates.

Q: Can Jingzhou wedge wire screens operate in corrosive environments?

A: Yes, all Jingzhou products are made from corrosion-resistant stainless steel (304/316L), making them ideal for harsh chemical or saline conditions.

Q: How can I determine the correct slot size for my application?

A: Jingzhou offers customization based on your particle size requirements—contact us for technical support.

Q: Are your wedge wire screens suitable for upgrading existing systems?

A: Yes, our products can be manufactured to fit most standard housings or customized dimensions to integrate seamlessly with your current setup.