Understanding Slot Size in Filtration

What Is Slot Size in Wedge Wire Screens

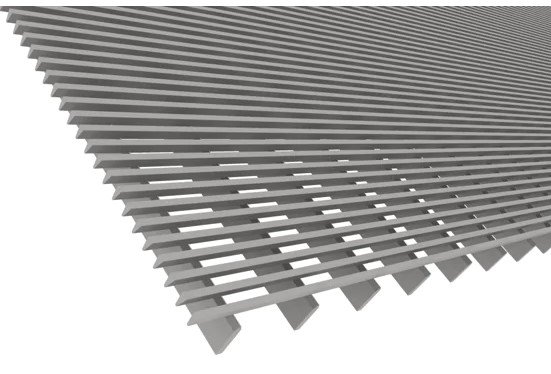

Slot size is just the little opening between two V-shaped stainless steel wires after they’re welded to the support rods. That gap decides exactly what gets through and what stays behind. Go tighter, and you stop much smaller stuff.

Wedge wire holds up for years, keeps the slots dead-on even when the pressure climbs or the liquid eats regular screens for lunch. That’s why water plants, mines, and food factories swear by it.

Why Small Slot Variations Matter

Jump 0.02 mm one way or the other, and the whole job changes. A juice producer once went from 0.25 mm to 0.27 mm on a juice line—suddenly, apple pulp started sneaking past and clouding bottles. They lost two full shifts cleaning tanks before switching back. On the other hand, dropping just 0.03 mm on a groundwater screen cut sand carry-over so much that the pumps stopped wearing out every six months.

Jingzhou Wedge Wire Screen Overview

Key Features of Jingzhou Wedge Wire Screens

Jingzhou builds everything from proper 304 or 316L wire stock. The V-wires face outward, so solids slide off instead of jamming in. Slots stay within a hair’s width from 0.02 mm all the way up to 3 mm—whatever the job needs.

Recommended Models for Fine Filtration

Dead-on 0.25 mm slot, durable basket that fits perfectly into most industrial filtration systems. Food processing plants and chemical factories favor these because product flow stays smooth and cleaning cycles are easier to manage.

0.5 mm slot on a round basket. Perfect for thick slurries or oil-water jobs where you need decent flow but still have to keep the mids out. Coal plants run these hard, and they keep pumping without choking.

Impact on Filtration Efficiency

How Slot Size Affects Flow Rate and Clogging

Tighter slots grab more junk, but the liquid slows down, and the screen can plug fast if the solids load is heavy. Open it up a touch, and everything flies through—sometimes too much of the wrong stuff.

Matching Slot Size with Application Needs

City water guys usually stay 0.2–0.5 mm to keep grit out of the pipes. Mines and paper mills open up to 1–2 mm, so the pumps don’t starve. Pick wrong, and you’re either hosing screens every shift or sending dirty water downstream.

Jingzhou keeps every common size on the shelf and can tweak anything in a week or two.

Material and Build Quality Considerations

Benefits of Stainless Steel Wire Construction

Real stainless doesn’t rust, doesn’t stretch, and laughs at acid. Run 316L in hot caustic or salty brine, and it still looks new after ten years.

Jingzhou Manufacturing Precision Advantage

CNC welders lay every bead perfectly while lasers check slots in real time. A six-meter panel has the same opening corner to corner—no surprises.

Need something nobody stocks? Draw it, send it over. They’ll roll the profile, space the rods, and ship whatever shape fits your pipe.

Choosing the Right Jingzhou Product

Factors to Consider When Selecting a Screen Model

Ask yourself three quick questions:

- How small is the smallest particle I have to stop?

- How hard does the pump push?

- Is the liquid clean water or a nasty chemical soup?

Tell our engineers, and we’ll point you to the exact model instead of guessing.

Available Customization Options from Jingzhou

Slot down to 0.02 mm, any V or trapezoid wire you want, rods wherever they need to be, flat, round, half-pipe, curved—whatever drops in place.

Our main products include special-shaped wires of different materials (stainless steel, copper, titanium), welding wires, ultra-fine wires, and wedge wire filter screens.

FAQ

Q: How do I choose the correct slot size for my application?

A: Determine the smallest particle you need to block, then select a slot 10–20% smaller. For most wastewater or solid-liquid separation tasks, the 0.25 mm works effectively.

Q: Can small differences like 0.02 mm really affect performance?

A: You bet. In fine polishing, that 0.02 mm can be the difference between crystal-clear output and a failed batch.

Q: Are Jingzhou screens suitable for corrosive environments?

A: Yes—304 for normal stuff, 316L when salt, acid, or hot cleaners are around.

Q: Can I request a customized wedge wire screen for my equipment?

A: That’s what we do best. Send the drawing and conditions; you’ll have it in a couple of weeks.