Understanding Wedge Wire Screens in Food Processing

What Are Wedge Wire Screens

Wedge wire screens (V-wire screens) are made by forming stainless steel wires into a V-shaped profile and welding them onto support rods. This design creates narrow, uniform slots that allow liquid to pass while retaining solids. Because the V-shape reduces clogging and handles heavy loads, these wedge wire screens operate reliably in demanding food-processing environments. Slot sizes range from 0.05 mm to 5 mm, suitable for everything from fine whey separation to coarse vegetable filtration.

Why Wedge Wire Is Ideal for Food Applications

Food plants need equipment that cleans quickly and leaves no hidden spots for bacteria. The smooth, curved wedge-wire surface washes down easily during CIP cycles. Materials like 304 and 316L stainless steel resist acids, salt, dairy enzymes, and fruit juices. Many wedge wire screens remain corrosion-free even after years in juice, pickle, dairy, and brine applications.

Jingzhou’s Custom Wedge Wire Screen Solutions

Jingzhou Wedge Wire Sieve Baskets

Made from high-quality 304 or 316L stainless steel, Jingzhou’s Wedge Wire Sieve Baskets feature precise slot openings ranging from 0.02 to 2 mm. The robust design resists bending and handles pressure fluctuations reliably. In dairy processing, using baskets with 0.1 mm slots ensures efficient separation of whey from curd while maintaining high protein retention.

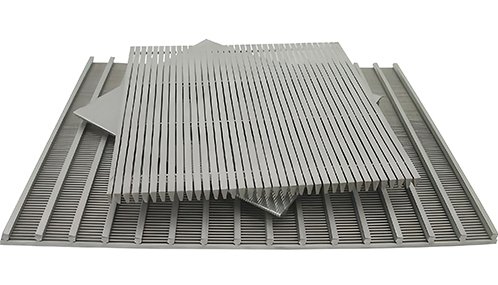

Jingzhou Wedge Wire Screen Panels

The panels feature reinforced edge welding to stay straight under heavy loads of grains, beets, or corn. Breweries use them under lauter tuns for faster runoff, while sugar factories rely on them for efficient juice drainage on vacuum belts.

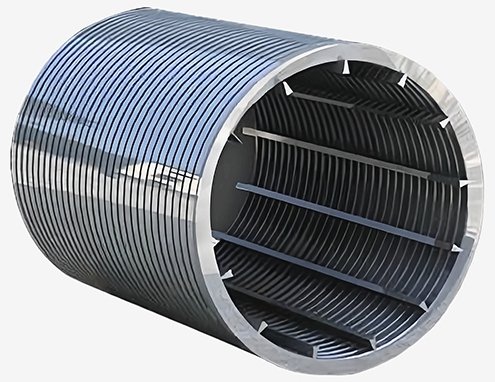

Jingzhou Wedge Wire Screen Cylinder

These Screen Cylinders—static or rotating—handle apple mash, potato slurry, citrus pulp, and more. Custom double-layer designs can perform coarse and fine filtration simultaneously; one citrus plant uses 2 mm outer / 0.2 mm inner slots to refine juice in less space.

Customization Capabilities from Jingzhou

Tailored Slot Openings and Dimensions

We customize slot size, panel width, length, drum diameter, and even curved shapes for older machines. A tomato processor needed 0.15 mm slots on a 1.2 m-wide panel to keep seeds out of passata—we delivered a drop-in replacement within three weeks.

Surface Finish & Welding Precision

Electro-polishing creates a mirror finish that rinses clean instantly. All welds are TIG-welded under argon for smooth, hygienic joints without cracks or burn marks. This ensures compliance during audits and prevents microbial growth.

Benefits of Using Jingzhou Screens in Food Processing Lines

Improved Product Quality and Safety

Finer slots reduce turbidity and contamination. A juice manufacturer switching to 0.08 mm screens can reduce juice cloudiness from 8 NTU to 0.8 NTU, improving appearance and consistency while effectively reducing customer complaints.

Enhanced Equipment Longevity & Efficiency

Wedge wire lasts significantly longer than perforated plates. A yogurt plant extended replacement intervals from six weeks to eighteen months. With smoother screening surfaces, pumps and downstream equipment also experience fewer blockages and wear.

Compliance with Food Industry Standards

All stainless steel materials come with full mill certificates and meet FDA and EU 1935/2004 food-contact standards. Documentation is audit-ready for easy verification.

Applications Across the Food & Beverage Industry

Dairy Industry Filtration Needs

Wedge wire efficiently removes straw and debris at intake (0.5 mm) and preserves valuable protein during whey drainage with fine 0.2 mm slots. In mozzarella brine systems, 1 mm screens collect curd fines and keep brine clean for repeated cycles.

Beverage Production Processes

Breweries gain 30–40% faster lauter-tun runoff using wedge wire flat panels. Juice plants employ 3 mm coarse drums to remove peel and rag, and 0.3 mm finishing drums to achieve high clarity.

Solid-Liquid Separation in Meat & Vegetable Processing

Meat processors recover fine protein particles (0.25 mm) from broth instead of losing them to wastewater. Vegetable lines use wedge wire to retain usable potato or vegetable pieces while sending clean water onward to treatment.

Jingzhou’s Commitment

We focus on delivering wedge wire screens that operate reliably across three-shift plants and high-volume production lines. From artisan cheese makers to large beverage factories producing millions of bottles per day, we build exact-fit wedge wire screens and support them for years.

FAQ

Q: What makes wedge wire screens better than perforated plates?

A: The V-shaped profile deflects solids instead of trapping them. Plants that once spent hours unclogging perforated holes report near-zero blockage after switching.

Q: Can I get a screen customized for my existing machine?

A: Yes. Send drawings or the old screen, and we replicate dimensions, slots, and bolt patterns for a drop-in fit.

Q: How do I clean wedge wire screens?

A: They integrate with standard CIP cycles. If removed, a pressure washer with 80°C water cleans them easily—especially with electro-polished surfaces.

Q: Are they safe for acidic or salty foods?

A: 316L stainless steel resists strong acids and brine. Seafood and citrus factories report a decade-long service life without corrosion.