In the demanding world of industrial processing, the choice of material is the single most significant factor in determining the lifespan of equipment. While carbon steel is often considered for its low initial cost, it frequently becomes a financial liability in critical applications such as petrochemical refining, water treatment, and mineral processing. For these sectors, stainless steel is not merely an upgrade; it is a necessity. At Jingzhou, we have spent over a decade perfecting the R&D and production of stainless steel profile wires to ensure our clients avoid the “big financial losses” associated with material failure.

The Critical Performance Gap: Stainless Steel vs. Carbon Steel

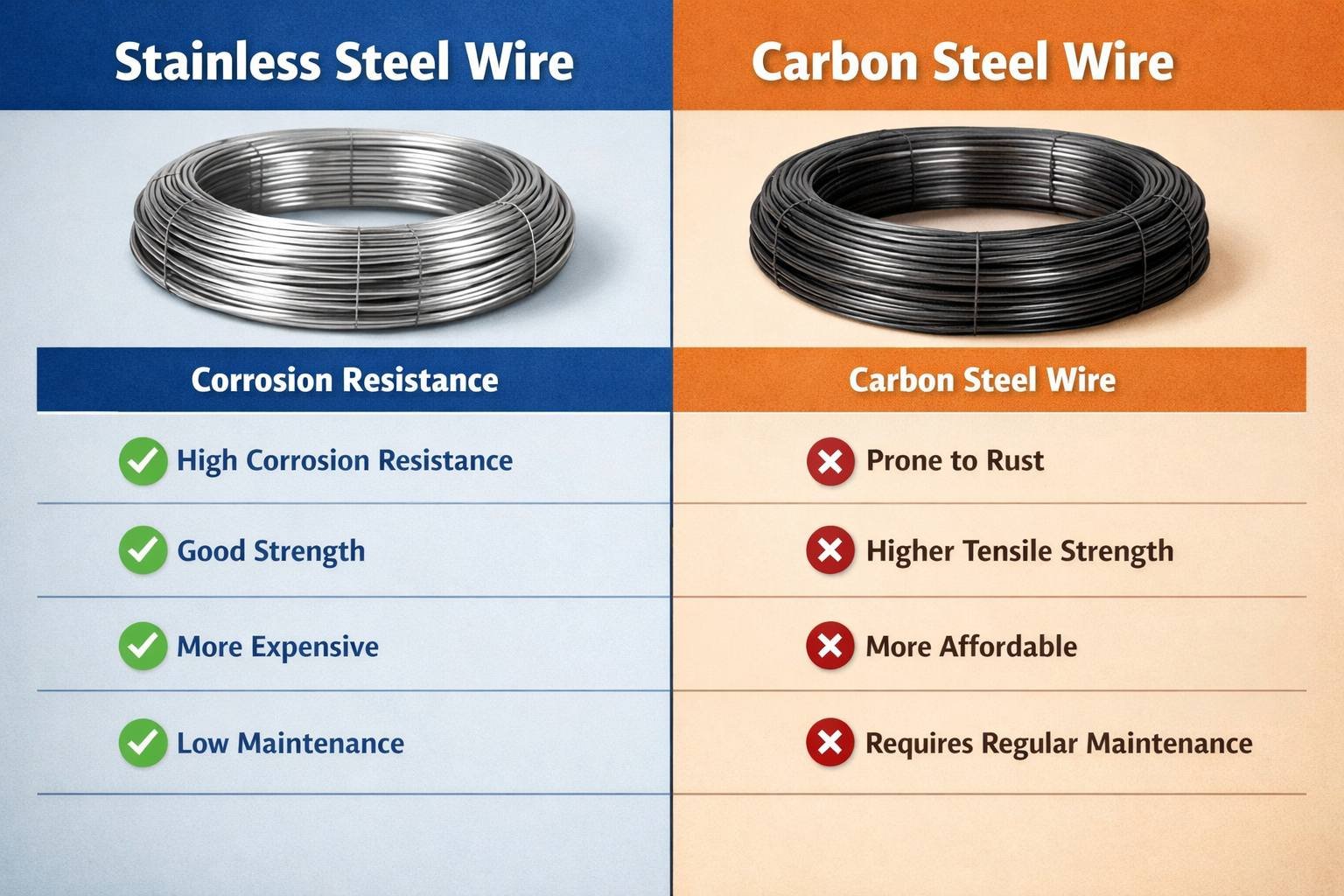

The primary difference between the two materials lies in their reaction to the environment. Carbon steel is highly susceptible to oxidation, leading to rust and the eventual loss of structural integrity. In contrast, the stainless steel used in Jingzhou products—primarily the 300 series and exotic alloys—contains chromium, which forms a self-healing passive layer. This fundamental difference results in a “lower total cost of ownership,” as stainless steel requires “no replacement cost” and fewer production stops.

Technical Advantages of Stainless Steel in Filtering and Separation

Superior Corrosion Resistance in Aggressive Environments

Critical applications often involve contact with aggressive media. In the petrochemical industry, filters must withstand crude oil containing sulfur, nitrogen, and metals. Carbon steel would degrade rapidly under these conditions. Jingzhou utilizes materials like 316L and 321 stainless steel, which offer increased resistance to chemical softening and corrosion. This is equally vital in the water treatment industry, where filters must remain pure while processing wastewater or seawater.

Mechanical Strength and Resistance to Structural Fatigue

Critical applications often subject filter elements to high pressure and heavy loads. Stainless steel profile wires are known for “great strength” and a “self-supporting structure. Our Vee-Wire elements are welded into a “rugged construction” that provides “exceptional resistance to collapsing or buckling”. Carbon steel, while strong, loses its load-bearing capacity as it thins due to corrosion, whereas stainless steel maintains its “mechanical strength” and “structural integrity” over a “long service life”.

Thermal Stability and Non-Clogging Surface Dynamics

In food and beverage processing, such as juice or beer filtration, materials must withstand high-temperature sterilization without warping. Stainless steel maintains its shape and precision under extreme heat. Furthermore, Jingzhou’s V-shaped wire profiles create a “non-clogging surface”. The smooth surface of stainless steel reduces material adhesion and abrasion, ensuring “high flow rates” and “hydraulic efficiency” that carbon steel cannot sustain as its surface roughens with age.

Jingzhou’s Stainless Steel Solutions for Demanding Industries

High-Durability Conveyor Belts for Harsh Processing Cycles

In environments involving drying, cooling, or chemical treatment, the Conveyor belt (processing belt) is under constant stress. Jingzhou’s stainless steel belts are designed for “high-wear applications” that require a clear, free-slotted surface. Unlike carbon steel belts that might rust and contaminate the product—a critical failure in the pharmaceutical or food sectors—our stainless steel belts are “easy to clean” and offer a “long-lasting” solution with “fewer change-outs”.

Precision-Engineered Wedge Wire Screens for Load-Bearing Filtration

The Wedge wire screen serves as the backbone for many separation processes. Whether used as support for sand beds, activated carbon, or catalysts, these screens must handle “extremely high loads. Jingzhou ensures these screens provide a “large open area” and “low pressure drop”. By choosing stainless steel over carbon steel, operators benefit from “precise slot openings” that do not widen over time due to corrosion, ensuring that the “classification” and “sizing” of materials remain accurate throughout the screen’s life.

The Jingzhou Commitment: Quality Assurance and Customized Excellence

Advanced Quality Control and Material Verification

Operating from our 18,000-square-meter facility in Tianjin, Jingzhou employs a spirit of “excellence and innovation”. To distinguish our high-performance stainless steel from inferior materials, we use Spectrometer Analysis to verify the exact alloy grade. We also utilize Infrared Detectors to monitor dimensional variation and Tensile Force Meters to confirm the “mechanical performance and durability” of every coil.

Fully Customized Engineering and Manufacturing Services

At Jingzhou, we recognize that every critical application has “specific application requirements. We provide a “high level of adaptability” through our customized service model. Our technical team offers:

- Customized profile shapes, including V-shaped, T-shaped, and triangular wires.

- Customized slot openings from 25 µm up to 0.984 inches.

- Customized framing and assembly options, such as “L”-shaped or ordinary frames.

By leveraging our customized manufacturing capabilities, industrial leaders can obtain filtration elements that are specifically engineered for their “individual system need”. Whether you are upgrading an existing plant or designing a new expansion, Jingzhou’s stainless steel solutions offer the reliability and precision required for the world’s most critical operations.

FAQ

Q: Why is Jingzhou’s stainless steel better for food processing than carbon steel?

A: Our stainless steel is “easy to clean,” “abrasion resistant,” and does not rust, ensuring product “purity and safety.

Q: Can I get a customized slot size for a specialized conveyor belt?

A: Yes, we offer full customized services for slot sizes starting from 25 µm to meet your “exact specifications”.

Q: How do you guarantee the material grade of your stainless steel?

A: We use spectrometer analysis to perform precise material composition testing and provide analysis certificates upon request.

Q: Is the lead time longer for a customized stainless steel order?

A: Generally, it is 10-20 days for customized orders, depending on the quantity and complexity of your requirements.